The Small Shop 5.5" (5 Speed) Hold and Fold Review

Nov 12, 2013 23:02:56 GMT -5

bullardino and pantherf..-Email Not Valid like this

Post by TRM on Nov 12, 2013 23:02:56 GMT -5

Photo Etch Bending Tool

5.5" (5 Speed) Hold and Fold

Review

From the

The Small Shop

Model No. – SMSoo4

Maker

The Small Shop

a.k.a.

Kalama Precision Machine

MSRP - $69.99 US

The Small Shop, as on in the same of Kalama Precision Machine; a family owned machine shop, contracting with manufacturers to supply detail parts and sub-assemblies, are one in the same and have been producing the original photo etch bending tool, “The Hold & Fold since the summer of 2002. The Small Shop sprang up in 2007. Since then, The Small Shop has added a number of items to the list of modeling tools to aid the modeler in working with not only photo etch parts but scale nut, bolt and rivet tools and a wide variety of small hand tools and blades.

To many of you, The Small Shop and/or the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold are not new news, as the Small Shop has been around for a few years and the 5.5” Bending Tool has been out just as long. However, I have the pleasure of giving this product the once over for the Modelers Social Club Forum!

Personally I have always been the pliers/flat nose tweezers guy when it comes to bending photo etch (PE). I always thought the need was marginal and the cost could better be applied to kits or paint. This may be a bit early in the review but I never realized how wrong I was.

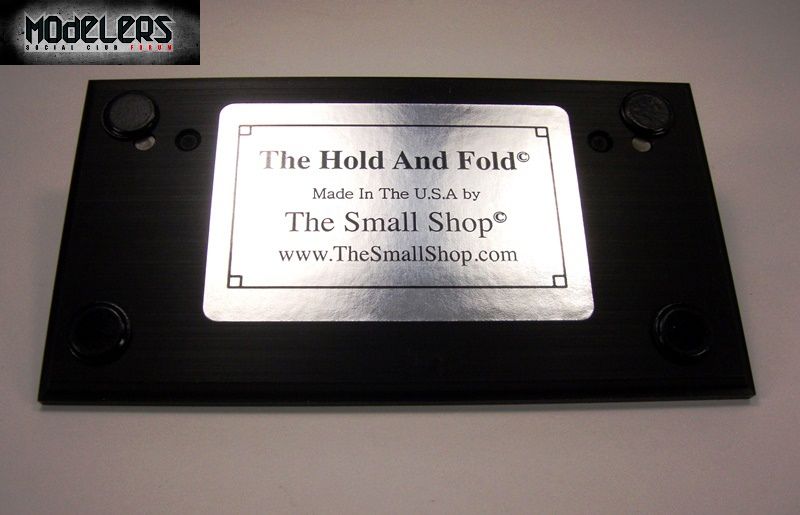

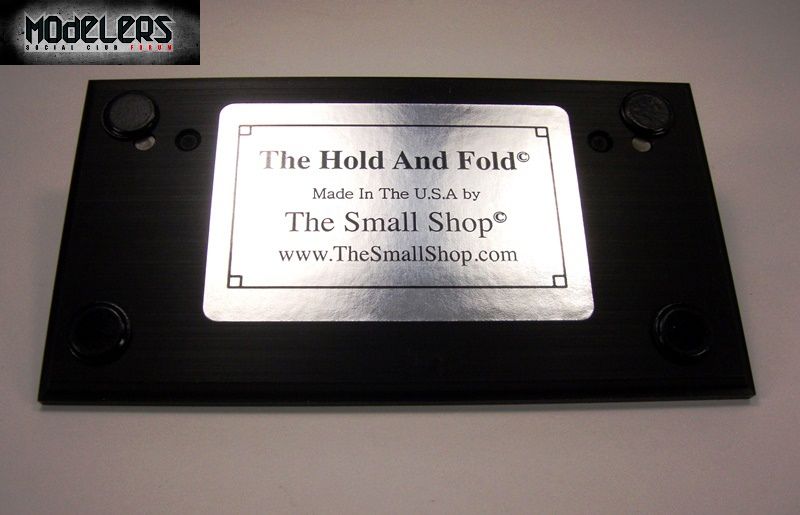

I have been fortunate enough to obtain the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold, supplied generously to MSC from our friends at The Small Shop. Provided in a sturdy flip-top cardboard box the Photo Etch Bending Tool comes with the PE workstation, one razor blade, one 5 inch Folding Blade and a two-page instruction sheet.

Instructions

thesmallshop.com/instructions/5%20Speed.pdf

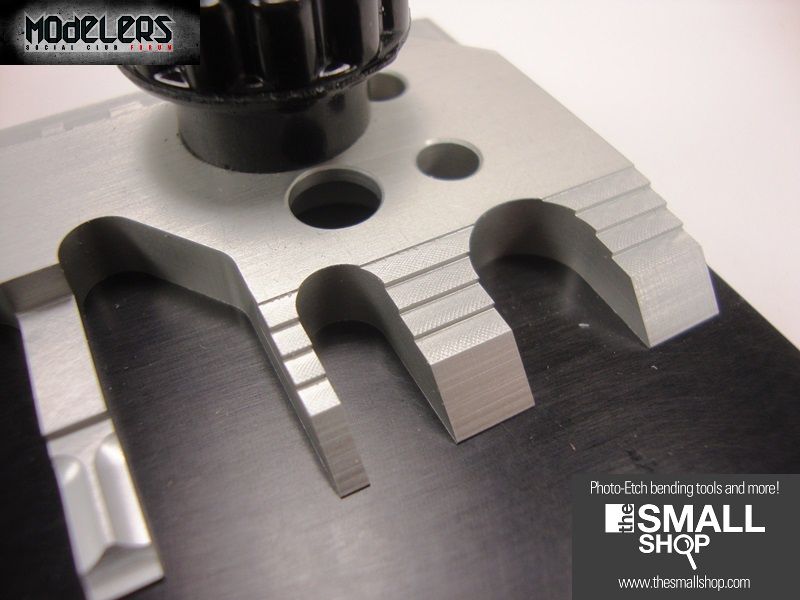

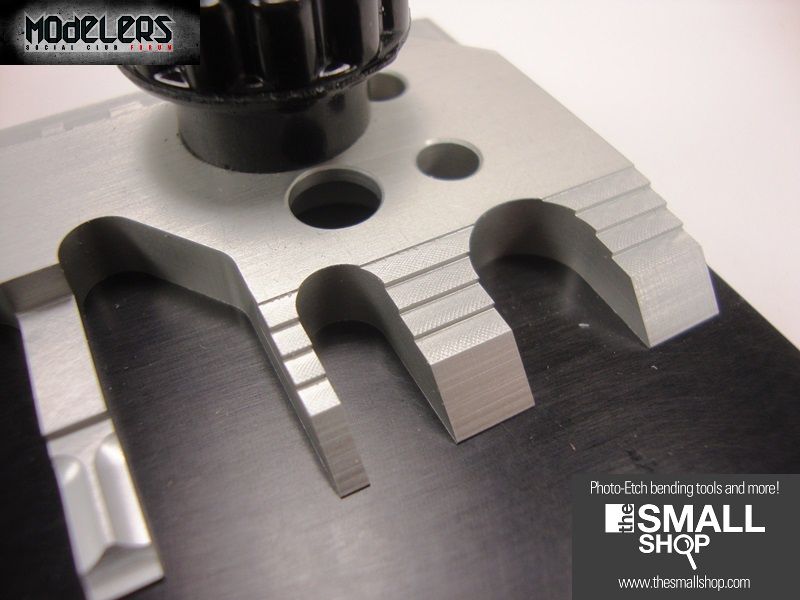

All of the PE Workstations, from The Small Shop are precisely milled from solid aluminum stock. The top jaw to the Bender has a dull aluminum mill finish to it and the strong base plate has a black anodized finish. There are 16 Bending Fingers milled into the top jaw of the bender; each one to different widths and lengths to accommodate a multitude of material shapes and thicknesses. The top plate is fastened down with two threaded knobs. There is aptly named Power Wedges on one edge to facilitate the bending of brass stock that has no scoring.

There is a pyramid design incorporated into each of the fingers which aids in the full bending of u-shape parts. There is a section on the tools known as the Pre-Etch Bending Beams. This is designed to aid in bending pre-etched parts such as small tie downs, Aber German Clamps and Sherman Headlamp guards along with flat brass or wire shapes.

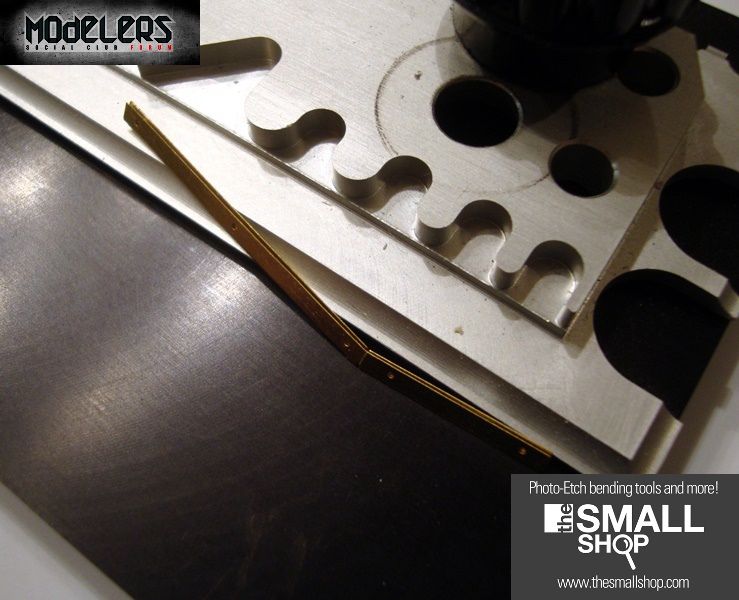

Having a chance to play around with the bender I figured I would try out some parts I run into from time to time and will give the tool a good work out. I wanted to try a full bend-over of a part as seen with Shurtzen Skirt edging. This part has two bends that need to fold completely over each other to make a receiving slot for the mesh side skirt armor. A quick over bending of the part using the razor blade and then quickly slide the part under the jaw of the Bending Tool and then tighten the threaded knobs down; flattening the part. This was extremely easy to do with the bender.

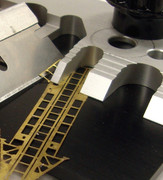

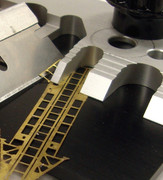

After trying the tool out on a couple Panzer parts, I wanted to give some 1/700 scale ship PE a shot. I had an unused IJN Catapult frame. Considerably smaller than some 1/35 armor parts, the bends again were simple to maneuver through and quickly the part was bent into shape. Of course I jumped up a scale to 1/350 and tried a Catapult from the USS Arizona…again, the 5.5" (5 Speed) Hold and Fold made light work of the job.

I am working on a 1/16 scale FT-17 tank at the moment and the driver's pedals need to have small curved skid plates added to the tops. I just needed to find the correct size curved section, slide the piece in, bench and done!

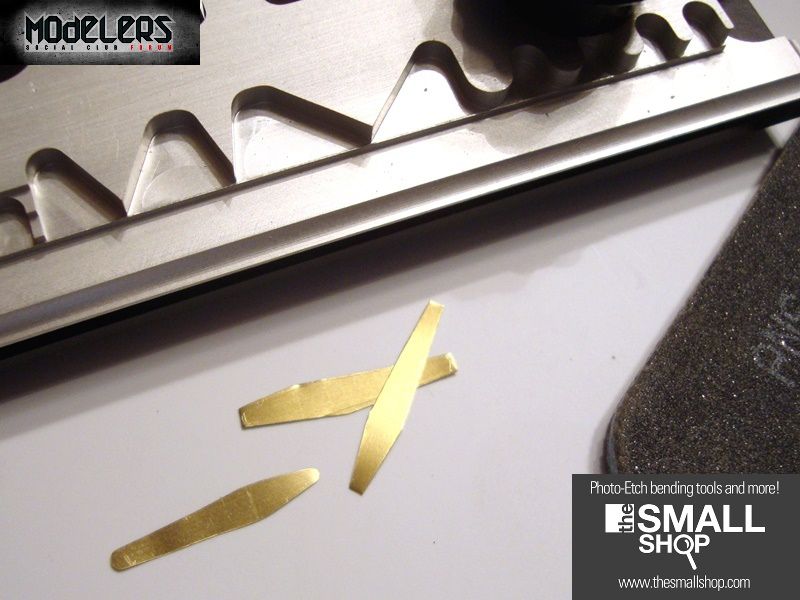

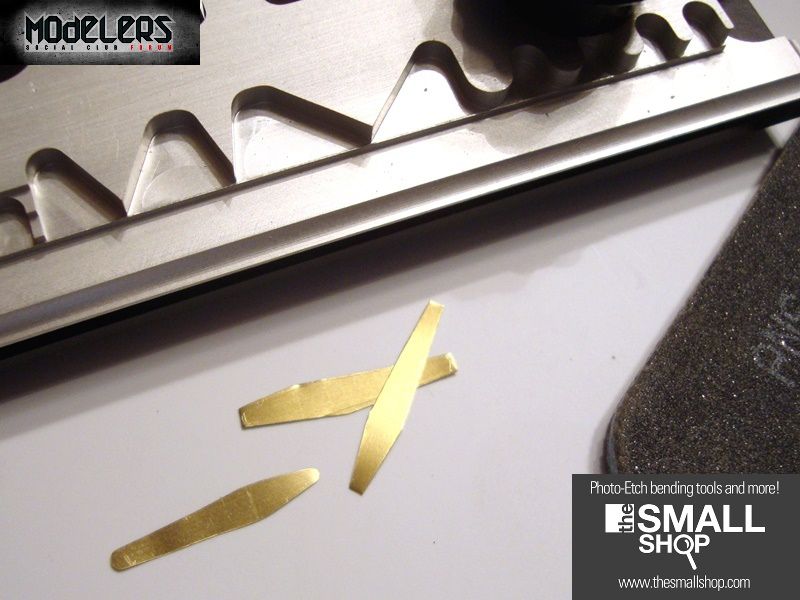

Each one of the bending fingers are spaced nicely across one side allowing plenty of room while bending not only small parts but larger more complex parts. Taking advantage of the tool being on the bench, I wanted to try it out on some scratch work. I needed to make up three control arms for the braking system on a flatbed rail car. Using some thin shim stock I cut three basic shapes out; with one shaped to what I needed, I stacked all three on top of each other and used the tool to clamp down and hold the parts tightly to sand them into identical shapes with a sanding stick. I was very pleased with the ease at which I was able to shape the parts. Then using some extra shim stock I tried out bending some angles on a pieces of brass that was not pre-etched….success!!

Finally, I wanted to try out a suggestion from the instructions where the 5.5" (5 Speed) Hold and Fold can be used to construct Fruils. Albeit, the edge is a great straightedge, I found I had an easier time after inserting some styrene square stock in the jaw of the tool first. I thought it might be the particular track, Pz.Iv Ostketten tracks but I did attempt a set for a Merkava II. The straight was an exceptional help in keeping the tracks true and the four rubber feet on the base of the Bender work fantastic keeping the tool stationary while bending and pressing on the tool.

Conclusion

I thought I would never have the need for a tool like this but I have to say, hands down, this is an extremely useful tool. For the obvious reasons, bending of photo etch parts is turned from a complex and tedious task into an enjoyably easy process. Being multifaceted whit a wide variety of bending fingers, cutouts for pre-etched parts and a large straightedge there is a multitude of applications. If you add in the fact the tool can be used as a micro brake press for the construction of scratch brass and styrene parts makes this tool a 10/10 for the modern model builder’s bench. The price might seem high to some whereas it is about the cost of the average mid-ranged kit but the benefits in the long term I feel are well worth the cost when it comes to The Small Shop Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold.

The Small Shop does offer many designs of the Hold and Fold and you are sure to find one to fit you need at the right price. The Small Shop also offers PE Rolling Sets, PE Cut-off Kits as well as The Nutter Set which aids in the making of scale model nuts and rivets.

I would like to that The Small Shop for providing MSC with the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold for review.

Please take the time to visit The Small Shop to take a look at all the PE workstations and other fine tools they offer!

5.5" (5 Speed) Hold and Fold

Review

From the

The Small Shop

Model No. – SMSoo4

Maker

The Small Shop

a.k.a.

Kalama Precision Machine

MSRP - $69.99 US

The Small Shop, as on in the same of Kalama Precision Machine; a family owned machine shop, contracting with manufacturers to supply detail parts and sub-assemblies, are one in the same and have been producing the original photo etch bending tool, “The Hold & Fold since the summer of 2002. The Small Shop sprang up in 2007. Since then, The Small Shop has added a number of items to the list of modeling tools to aid the modeler in working with not only photo etch parts but scale nut, bolt and rivet tools and a wide variety of small hand tools and blades.

To many of you, The Small Shop and/or the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold are not new news, as the Small Shop has been around for a few years and the 5.5” Bending Tool has been out just as long. However, I have the pleasure of giving this product the once over for the Modelers Social Club Forum!

Personally I have always been the pliers/flat nose tweezers guy when it comes to bending photo etch (PE). I always thought the need was marginal and the cost could better be applied to kits or paint. This may be a bit early in the review but I never realized how wrong I was.

I have been fortunate enough to obtain the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold, supplied generously to MSC from our friends at The Small Shop. Provided in a sturdy flip-top cardboard box the Photo Etch Bending Tool comes with the PE workstation, one razor blade, one 5 inch Folding Blade and a two-page instruction sheet.

Instructions

thesmallshop.com/instructions/5%20Speed.pdf

All of the PE Workstations, from The Small Shop are precisely milled from solid aluminum stock. The top jaw to the Bender has a dull aluminum mill finish to it and the strong base plate has a black anodized finish. There are 16 Bending Fingers milled into the top jaw of the bender; each one to different widths and lengths to accommodate a multitude of material shapes and thicknesses. The top plate is fastened down with two threaded knobs. There is aptly named Power Wedges on one edge to facilitate the bending of brass stock that has no scoring.

There is a pyramid design incorporated into each of the fingers which aids in the full bending of u-shape parts. There is a section on the tools known as the Pre-Etch Bending Beams. This is designed to aid in bending pre-etched parts such as small tie downs, Aber German Clamps and Sherman Headlamp guards along with flat brass or wire shapes.

Having a chance to play around with the bender I figured I would try out some parts I run into from time to time and will give the tool a good work out. I wanted to try a full bend-over of a part as seen with Shurtzen Skirt edging. This part has two bends that need to fold completely over each other to make a receiving slot for the mesh side skirt armor. A quick over bending of the part using the razor blade and then quickly slide the part under the jaw of the Bending Tool and then tighten the threaded knobs down; flattening the part. This was extremely easy to do with the bender.

After trying the tool out on a couple Panzer parts, I wanted to give some 1/700 scale ship PE a shot. I had an unused IJN Catapult frame. Considerably smaller than some 1/35 armor parts, the bends again were simple to maneuver through and quickly the part was bent into shape. Of course I jumped up a scale to 1/350 and tried a Catapult from the USS Arizona…again, the 5.5" (5 Speed) Hold and Fold made light work of the job.

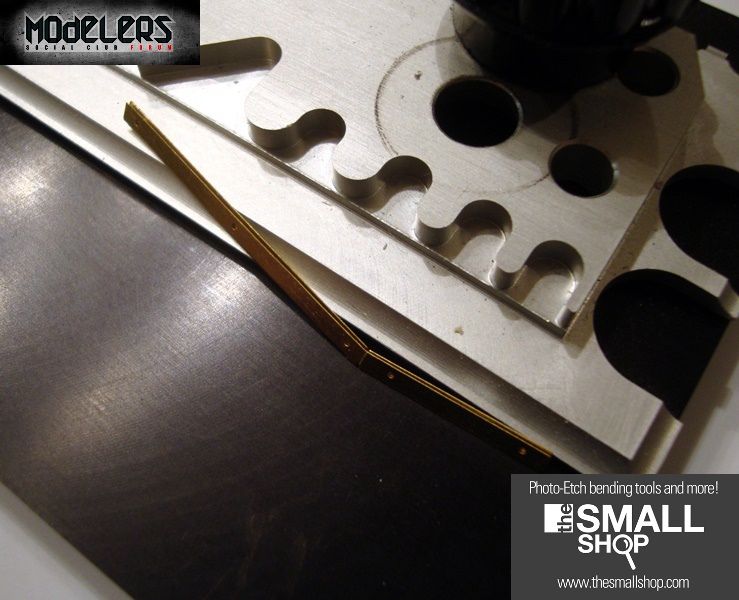

I am working on a 1/16 scale FT-17 tank at the moment and the driver's pedals need to have small curved skid plates added to the tops. I just needed to find the correct size curved section, slide the piece in, bench and done!

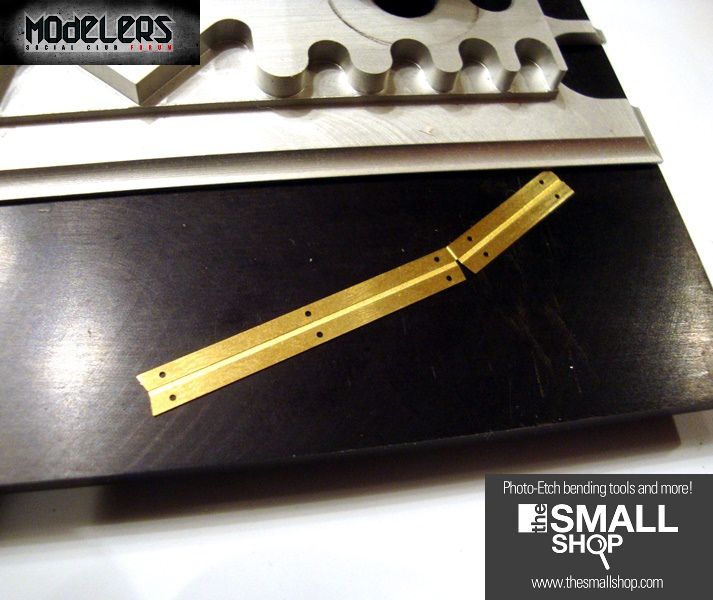

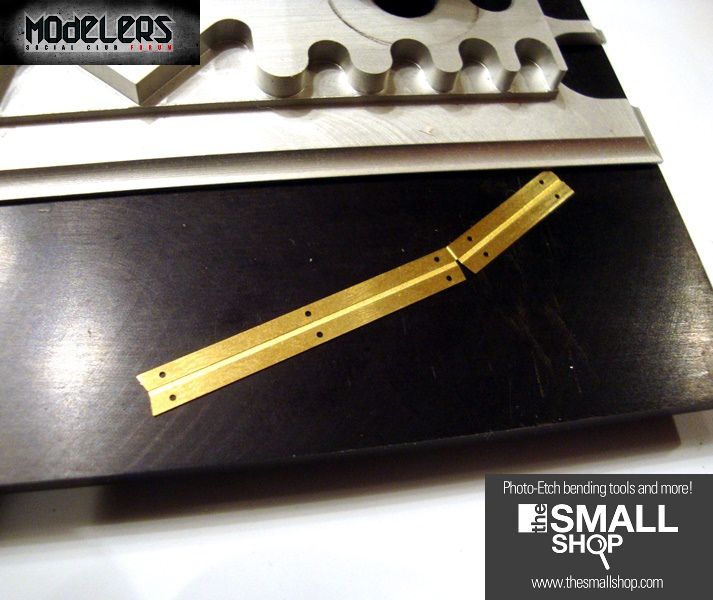

Each one of the bending fingers are spaced nicely across one side allowing plenty of room while bending not only small parts but larger more complex parts. Taking advantage of the tool being on the bench, I wanted to try it out on some scratch work. I needed to make up three control arms for the braking system on a flatbed rail car. Using some thin shim stock I cut three basic shapes out; with one shaped to what I needed, I stacked all three on top of each other and used the tool to clamp down and hold the parts tightly to sand them into identical shapes with a sanding stick. I was very pleased with the ease at which I was able to shape the parts. Then using some extra shim stock I tried out bending some angles on a pieces of brass that was not pre-etched….success!!

Finally, I wanted to try out a suggestion from the instructions where the 5.5" (5 Speed) Hold and Fold can be used to construct Fruils. Albeit, the edge is a great straightedge, I found I had an easier time after inserting some styrene square stock in the jaw of the tool first. I thought it might be the particular track, Pz.Iv Ostketten tracks but I did attempt a set for a Merkava II. The straight was an exceptional help in keeping the tracks true and the four rubber feet on the base of the Bender work fantastic keeping the tool stationary while bending and pressing on the tool.

Conclusion

I thought I would never have the need for a tool like this but I have to say, hands down, this is an extremely useful tool. For the obvious reasons, bending of photo etch parts is turned from a complex and tedious task into an enjoyably easy process. Being multifaceted whit a wide variety of bending fingers, cutouts for pre-etched parts and a large straightedge there is a multitude of applications. If you add in the fact the tool can be used as a micro brake press for the construction of scratch brass and styrene parts makes this tool a 10/10 for the modern model builder’s bench. The price might seem high to some whereas it is about the cost of the average mid-ranged kit but the benefits in the long term I feel are well worth the cost when it comes to The Small Shop Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold.

The Small Shop does offer many designs of the Hold and Fold and you are sure to find one to fit you need at the right price. The Small Shop also offers PE Rolling Sets, PE Cut-off Kits as well as The Nutter Set which aids in the making of scale model nuts and rivets.

I would like to that The Small Shop for providing MSC with the Photo Etch Bending Tool 5.5" (5 Speed) Hold and Fold for review.

Please take the time to visit The Small Shop to take a look at all the PE workstations and other fine tools they offer!

What Gary you talkin bout coz it aint me!

What Gary you talkin bout coz it aint me!

....Mehhh I am not a rivet counter either!

....Mehhh I am not a rivet counter either!