|

|

Post by wbill76 on Jul 7, 2018 18:03:03 GMT -5

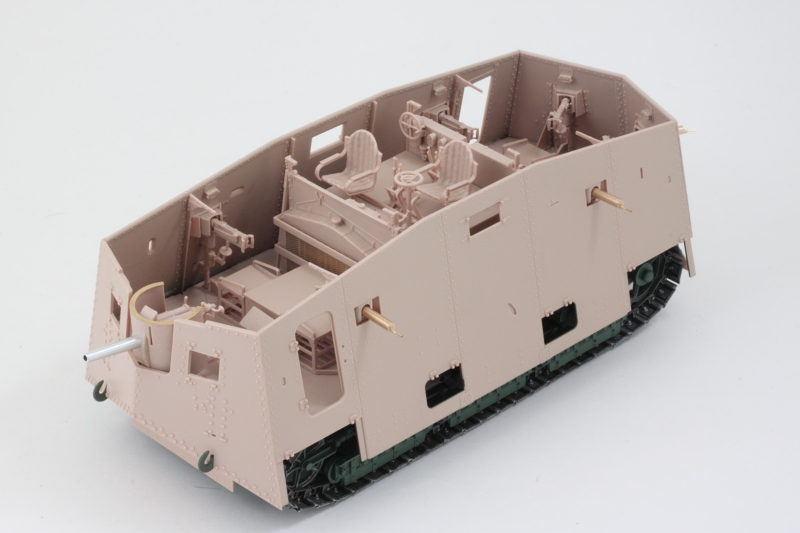

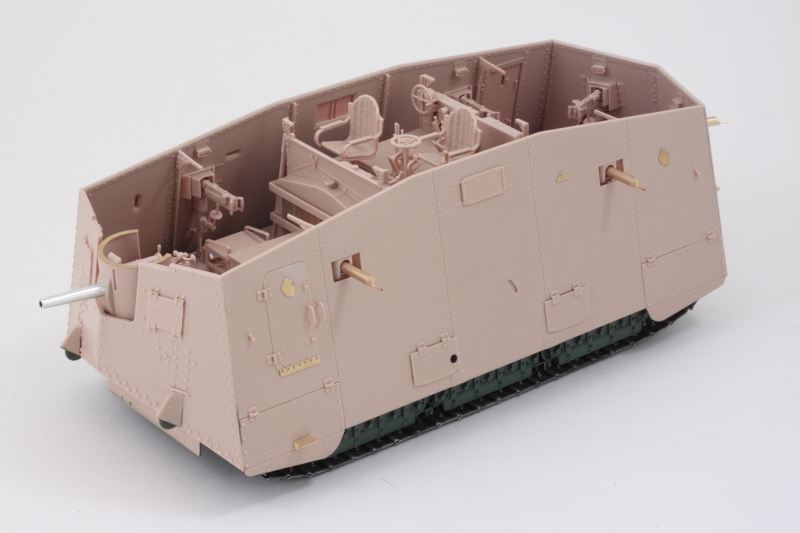

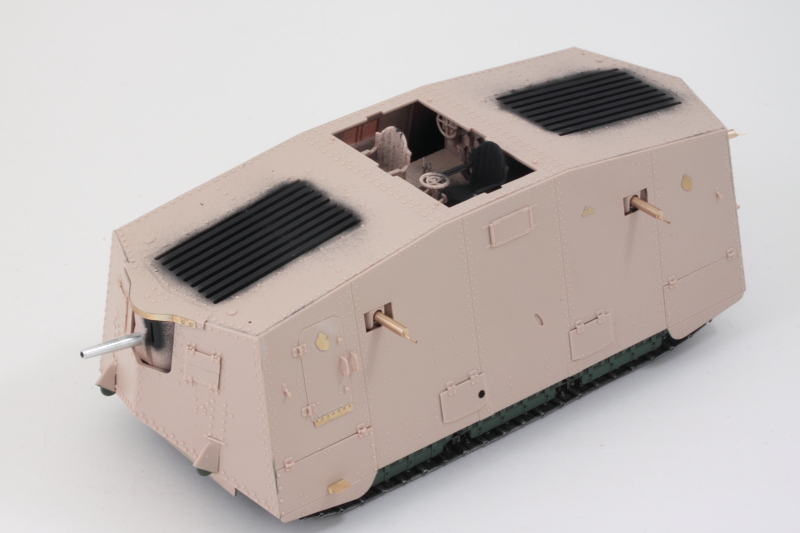

Nice stuff Bill It's my guess the hatches are not numerous or large on this which is too bad; that interior could be developed quite well if it could be seen post assembly Regards, Mark Thanks Mark! There are some hatches that can be opened up if you're so inclined...there are large crew-access doors on either side, one at the front, one at the rear on opposite sides, that can show off some of the interior. The roof also has some large grates for ventilation that would, potentially, allow some glimpses of more...but also presents the chief challenge in painting/masking if you go that route and the main reason I opted not to detail paint the interior on this particular build. |

|

|

|

Post by wbill76 on Jul 7, 2018 19:01:06 GMT -5

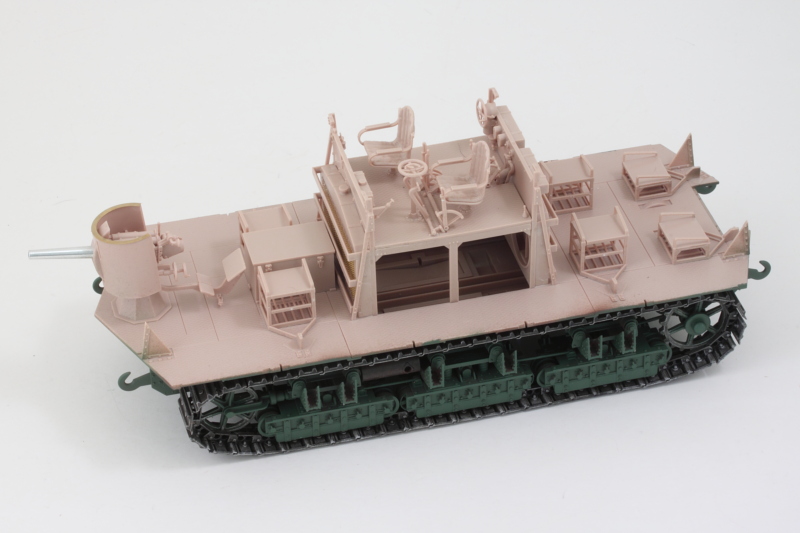

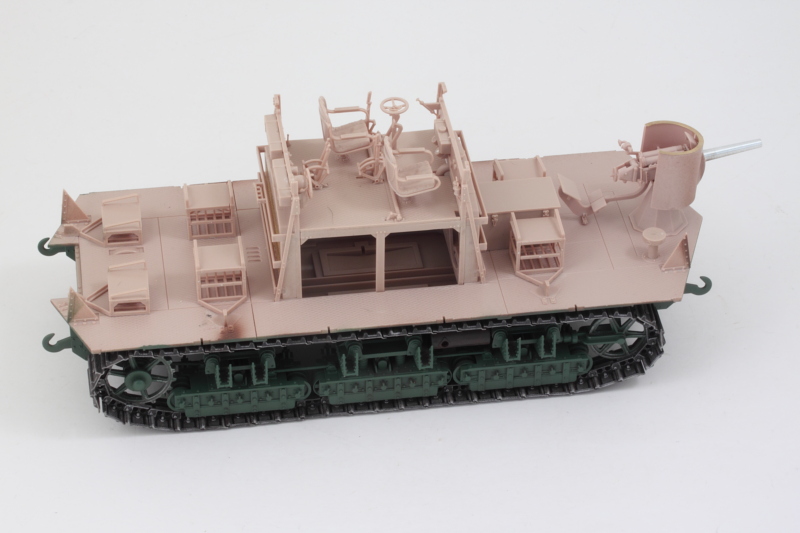

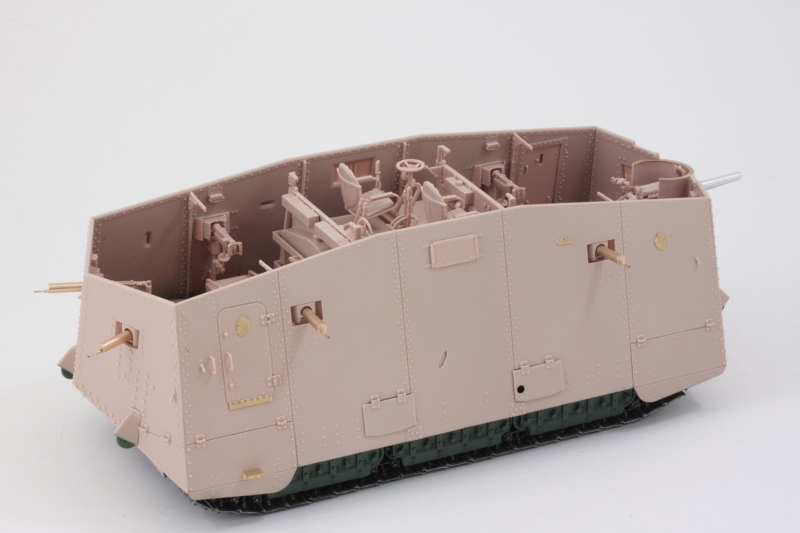

I followed up the work on the tracks yesterday with another wash application, this time using MM enamel Leather, to deepen the look a bit more and add another layer to the tones. It's a subtle effect that's more evident up close with the added bonus of slightly darkening the overall finish but not taking it all the way back to the Burnt Umber that I started with.  That meant it was time to install the tracks. They are a tight fit around the sprocket with just barely enough clearance with the fender surface, so I had to be careful there when feeding the run into position. I found it easiest to feed most of it through on the idler end and only running enough around the sprocket to meet up with the other end under the first set of road wheels. To get the links to connect up together I had to pull the runs together pretty snugly, almost as if they were a live-track, but it all worked out. A7V now has both shoes on!   That allowed me to resume with the instruction order of things and deal with Step 20. This installs all of the MGs into their respective positions on the hull side and rear plates. Everything fits pretty well here, but I did notice that due to the heavier brass barrels on the MGs, it's a lot easier for the side-mounted guns to slip off their swivel pins that support them on the interior side. I may end up fixing them in position before I attach the hull roof later on to avoid that happening in the future and being stuck with them pointing off at crazy angles unpredictably by accident.  Now came the big moment of truth! Steps 21 and 22 basically assemble the hull box and the angled front and rear plates that complete the whole arrangement. The side plates use small notches in the fighting compartment floor to help hold them in place, a nice design touch IMHO that if it wasn't there would mean you would need extra hands to get all the panels together. Careful use of liquid glue and finger pressure at the joins was all that was required to get the hull box together.  Next up will be adding the exterior hull details and then on to the driver's compartment box. |

|

|

|

Post by Tojo72 on Jul 8, 2018 8:19:50 GMT -5

Maybe I missed it Bill,but how much of the interior will be seen,just thru open doors or eill the roof be removable

|

|

406 Silverado

Global Administrator

Member since: November 2011

Posts: 10,418

Member is Online

MSC Staff

|

Post by 406 Silverado on Jul 8, 2018 8:36:25 GMT -5

Now she's looking like a tank....sort of lol. Good to see you spending time at the bench. Too hot and humid here the past week so no bench time for me.

|

|

|

|

Post by wbill76 on Jul 8, 2018 10:46:24 GMT -5

Rob, it's turning into the ultimate 'big box' on tracks! All I need is some Jawas to come out and offer some droids for sale...  Got to get in as much bench time as I can while the opportunity is available, hope you can stay cool in the meantime!  Maybe I missed it Bill,but how much of the interior will be seen,just thru open doors or eill the roof be removable , I decided not to personally show any of the interior due to several reasons (added-time factor, complications with painting, etc.) but the kit provides for multiple ways to show it off if you did want to go that route. Due to the way the kit is engineered, you need to build up a good part of the interior either way, so it's not something you can skip entirely if you follow my choice for the build. Since it isn't immediately obvious what is needed based on just the instruction drawings, I played it safe and built it all up as a precaution. You could leave the roof fully removable since it's got a tight friction fit on its own with the box structure as one option. You can also open one or both of the large doors on the main fighting compartment, there's a large rectangular hatch on top of the driver's compartment that appears like it can be posed open with a little adjustment (the instructions don't call out the option of open/closed for it and I haven't quite gotten there yet), and there are smaller viewports at the front near the main gun, the hull sides next to the driver's compartment seats, and on the armored box for the driver's compartment itself. On top of all that, there are large ventilation grates above the two main fighting compartment areas that will let in additional light to go with the various open doors/hatches depending, so you wouldn't need to resort to LED lighting or similar unless you really wanted to. HTH!

|

|

|

|

Post by Leon on Jul 8, 2018 13:43:30 GMT -5

Nice progress Bill! Looks really good with the shoes on.  |

|

|

|

Post by dupes on Jul 8, 2018 16:44:55 GMT -5

Totally agree about the sandcrawler-nature of this thing!

Question - wondering why you didn't start painting the interior before adding those side panels?

|

|

|

|

Post by wbill76 on Jul 8, 2018 18:41:34 GMT -5

Thanks Leon! It's moving along at a good clip now that the sides are attached.  Totally agree about the sandcrawler-nature of this thing! Question - wondering why you didn't start painting the interior before adding those side panels? , the simple reason is that I'm not going to display the interior, so there was no need to paint it. I've also heard from other builders that they have encountered issues with getting it all to fit together due to the tight tolerances that the kit is designed with. I've seen that already myself when I fit the tracks around the sprocket/idlers after both had been painted. That extra fractional mm of thickness made it a very tight fit that actually pulled paint off them when I fed the runs through in a couple of spots...definitely a case of it being very realistic but not desirable for the finish!  |

|

|

|

Post by wbill76 on Jul 8, 2018 18:42:03 GMT -5

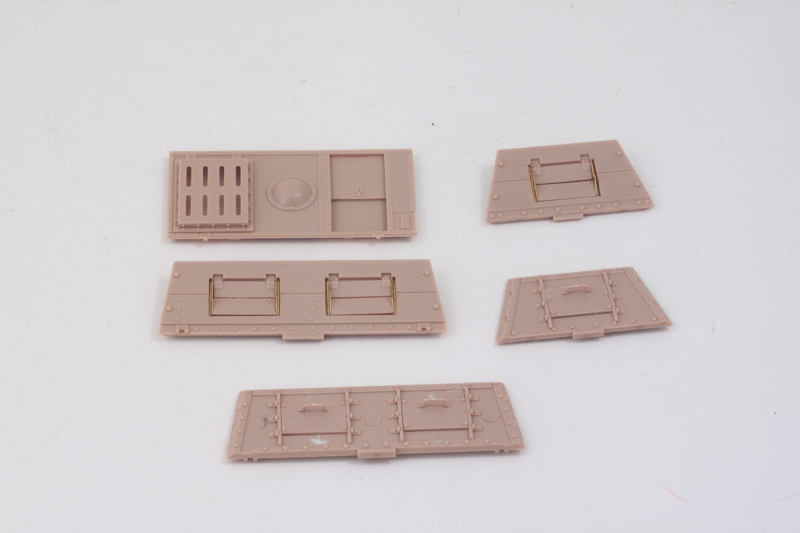

Picking up from yesterday, I moved on to adding most of the exterior details that are called for in Steps 23 to 26. Step 23 presents you with the option of showing the towing hook covers in the raised or lowered position for both the front and rear. I chose the lowered option but it's worth noting that on the rear set the covers overlap with the angled access hatches that aren't installed until Step 26. It's a good idea to hold off adding them until after those angled hatches are in place to avoid any issues. As mentioned previously, I'm posing all of the hatches closed so these were added to the sides and front as called for without issue. PE parts were added using careful application of liquid glue since they all use molded on small pins or rivets to help support them in place. The only details I left off out of these steps were the exhaust pipes and their support mounts. These connect up together in a three-part arrangement (including hollow ends) that will be a lot easier to paint/detail off the vehicle and then install as a single piece after I've completed the exterior painting. I did test fit the pipes to make sure they would fit smoothly through the holes in the access hatches and mate up with the exhausts now hidden away behind them as a precaution. I also went ahead and fixed the side-mounted MGs in position with some careful liquid glue applied to the swivel points on the interior posts. As I thought, it was way too easy to knock them off through regular handling and there's a lot more of that to come with the remaining work, so they are now fixed to avoid that problem popping up again.   Now it's on to the roof and box compartment for the driver as the last remaining structural piece. |

|

|

|

Post by dupes on Jul 8, 2018 19:00:43 GMT -5

Ahhh, gotcha! Surprised, then, that you took the time to install all of the not-structural parts.

|

|

|

|

Post by wbill76 on Jul 8, 2018 19:06:47 GMT -5

Ahhh, gotcha! Surprised, then, that you took the time to install all of the not-structural parts. I did that for 2 reasons. 1) There are some details that do play a structural role but aren't obvious until you get to later stages and see the interactions, so I played it safe when I couldn't be sure. Meng designed this kit very well IMHO and I didn't want to run the risk of screwing up something inadvertently by assuming. Now if it was a Dragon kit...  Some obvious things were left off like the crew weapons, the ammo belts for the MGs, the fold-down seats on the crew doors, etc. where I could be certain they weren't needed. 2) I might do another one in the future as a cut-away, so it was good practice as a 'trial run' to see whether or not I really want to try that again in the future and have this build to refer to if I did. It also helped to determine just what is/isn't visible through the different hatches and how much more work would be needed to mask/paint the different areas on that kind of a project. |

|

|

|

Post by dupes on Jul 8, 2018 19:09:36 GMT -5

Makes sense. I know for my current Tiger build there are a LOT of parts I won't be using because it won't be opened up (this time!).

|

|

adt70hk

Forum Moderator      November '24 Showcased Model Awarded

November '24 Showcased Model Awarded

Member since: November 2015

Currently attempting to build something decent!!! ;)

Posts: 2,849

MSC Staff

|

Post by adt70hk on Jul 9, 2018 7:55:20 GMT -5

Bill

That's coming together very nicely!

Well done.

Andrew

|

|

|

|

Post by wbill76 on Jul 9, 2018 8:45:19 GMT -5

Thanks Andrew!

|

|

reserve

Senior Member

Member since: July 2012

Si vis pacem para bellum

Posts: 2,373

Jul 11, 2012 9:11:45 GMT -5

Jul 11, 2012 9:11:45 GMT -5

|

Post by reserve on Jul 9, 2018 12:25:06 GMT -5

Sweet! As a veteran of many interior builds I can't tell you enough how dark it gets inside and how quickly all your painstaking work disappears as soon as you get the upper hull or roof on if you're not doing a cutaway

Regards,

Mark

|

|

|

|

Post by wbill76 on Jul 9, 2018 14:41:35 GMT -5

Sweet! As a veteran of many interior builds I can't tell you enough how dark it gets inside and how quickly all your painstaking work disappears as soon as you get the upper hull or roof on if you're not doing a cutaway Regards, Mark No kidding! I've had the same happen to me on more occasions than I'd care to count.  I'm working on the driver's compartment box now and picked up on a couple of things I hadn't noticed before. The first is that the entire space of the fighting compartment is open...meaning that there are narrow hallway-type access around the engine bays (makes sense if you think about it, have to be able to service them somehow!) but the empty bays themselves are not visible without using a dental mirror or similar. The second is that the entire roof of the driver's compartment box is hinged, indicating that it was designed to open as a whole piece in addition to there being separate hatches/openings over the driver's seat that have their own hinges. While Meng calls out different open/closed options elsewhere, it doesn't in that particular area. Doesn't mean you couldn't do it and definitely creates lots of options if you did want to show off that interior to maximum advantage. |

|

|

|

Post by wbill76 on Jul 9, 2018 17:30:38 GMT -5

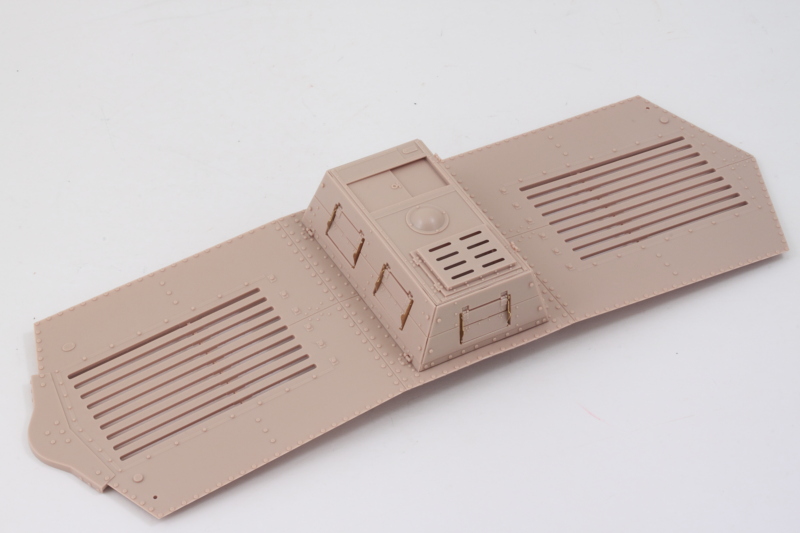

Sometimes things that at first glance seem like they will go together quickly can be deceptive in the amount of time needed in reality. Such is the case with the driver's compartment box that is covered under Steps 27-31. What ended up taking the most time was fitting the shutters to all the viewports since there are parts that need to install both inside and out on all four panels that make up the box. Included in those parts are small PE parts that create the support frames for the exterior that allow the covers to be posed either fully closed, half-open, or fully open. No matter which option is chosen, all of the parts are needed to make them work. The instructions include helpful diagrams that show how both the interior and exterior parts should be positioned and it's worth noting that these also apply for the side and front even though the diagrams are only shown once on the step for the rear plate's assembly. I used an Etchmate to bend the two small PE parts that go in on each side of the outside to hold the folding covers for each port. A bending tool of some kind is certainly necessary as the parts are small but do fit precisely in place with just a touch of liquid glue needed to hold them in place permanently. Step 30 deals with the roof plate for the box and has an interesting feature in the form of a sliding panel hatch for the commander that is designed to remain slidable if you're careful with the glue and assembly.  Step 31 assembles the box out of the 5 panels. My first instinct was to do this using the hull top to help pull it all together but I did a quick test fit of the roof to the vehicle and realized that the instructions have the box added later for a reason. The hull roof is molded with a slight angle/flex to it and this is useful for ensuring that it mates up properly with the hull before the compartment box is added. If you add the box, you lose some of that flex, making the job harder than it needs to be. With that said, I assembled the box as directed using regular glue to help hold the panels together until I had them positioned properly. Some liquid glue applied to the insides of the joins helped pull it all together nice and square along with the roof panel.  Just to make sure that I had it all lined up correctly, I did a dry-fit with the hull roof. Fits beautifully and I'll leave it like that until the glue fully sets up to avoid any complications.  Doing a quick test fit with the hull showed that I will need to spray some Flat Black under the large grate panels in the fighting compartment and under the driver's hatch to avoid any bare plastic being visible from the interior. Once that's taken care of, I can add the roof and compartment as the final elements before starting the exterior paint work. |

|

|

|

Post by dierk on Jul 10, 2018 4:18:40 GMT -5

Nice work on the 'box on tracks'

I dimly remember building the ancient version by (name escapes me) as a teen.

|

|

|

|

Post by wbill76 on Jul 10, 2018 8:26:18 GMT -5

Nice work on the 'box on tracks' I dimly remember building the ancient version by (name escapes me) as a teen. Thanks Dierk! I think you're referring to the Tauro offering? I don't think Emhar did one even though they had the British stuff, but it likely would have been one or the other! |

|

|

|

Post by dierk on Jul 10, 2018 9:30:08 GMT -5

Nice work on the 'box on tracks' I dimly remember building the ancient version by (name escapes me) as a teen. Thanks Dierk! I think you're referring to the Tauro offering? I don't think Emhar did one even though they had the British stuff, but it likely would have been one or the other! yup, that's the one |

|

406 Silverado

Global Administrator

Member since: November 2011

Posts: 10,418

Member is Online

MSC Staff

|

Post by 406 Silverado on Jul 10, 2018 9:54:03 GMT -5

She's looking goo bill. Yea take advantage of the time you can spend at the bench. I hit the bench on those less humid days, otherwise I'm trying to enjoy this summer weather.

|

|

|

|

Post by Leon on Jul 10, 2018 10:08:22 GMT -5

Coming along nicely Bill!

|

|

|

|

Post by wbill76 on Jul 10, 2018 18:40:22 GMT -5

Thanks Leon! She's looking goo bill. Yea take advantage of the time you can spend at the bench. I hit the bench on those less humid days, otherwise I'm trying to enjoy this summer weather. Living in the desert means humidity is rarely an issue...although this is currently our 'monsoon' season when we get a good bit of rain. Very rare that it means no modeling is possible since I've got the indoor paint booth arrangement but it can happen. Enjoy your good weather while you can!  |

|

|

|

Post by wbill76 on Jul 10, 2018 18:47:49 GMT -5

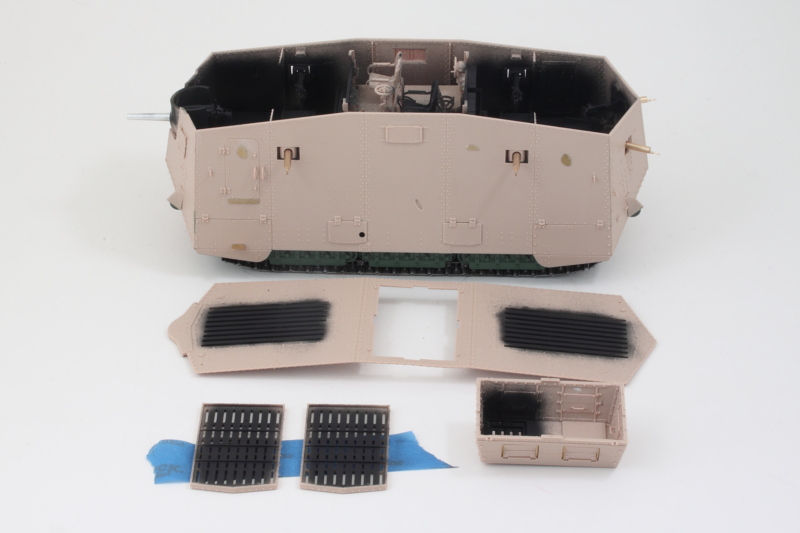

Following on from yesterday, I broke out the Flat Black to cover off the exposed areas inside the fighting compartment, driver's area, and the armored cover boxes for the ventilation grates. I had to pay particular attention around the main gun and MGs as a precaution as well before I cross the point of no return with the roof in place.  Time for the final steps! Step 32 wants you to add the ventilation grate covers to the roof before adding it in the final Step 33, but I found it better to wait so I could apply finger pressure where needed to get a solid join. I started at the front and used liquid glue and a small pointed brush to avoid over-applying it to the narrow join seams. Working my way back to the middle, I took advantage of the flex I mentioned earlier to ensure everything lined up like it should.  I used a #68 finger drill to open up the mount holes for the tow cable clamps as directed in Step 32 but left the clamps themselves off. That's because the markings call for very large iron cross decals over these grates, so those need to go on first and the clamps and tow cable added after. The covers and the driver's compartment box were added with liquid glue as well to round things out.  Now it's on to the exterior painting and finishing stage! |

|

ogrejohn

Full Member

Oct '23 Showcased Model Awarded

Oct '23 Showcased Model Awarded

Member since: June 2012

Go away or I shall taunt you a second time!

Posts: 1,305

Jun 1, 2012 17:33:59 GMT -5

Jun 1, 2012 17:33:59 GMT -5

|

Post by ogrejohn on Jul 11, 2018 17:41:14 GMT -5

Very nice work on such an ungainly looking beast Bill!

|

|

|

|

Post by wbill76 on Jul 12, 2018 10:58:20 GMT -5

Very nice work on such an ungainly looking beast Bill! No style points for the engineering design on this one that's for sure OJ! Thanks for the comments.  |

|

|

|

Post by Tobi on Jul 13, 2018 6:15:31 GMT -5

Very nice work on such an ungainly looking beast Bill! No style points for the engineering design on this one that's for sure OJ! Thanks for the comments.  Enough design style to make it a repair droid on the Death Star floors!  |

|

flmlm

Full Member

Member since: March 2016

Crack open that kit and smell the build ????

Posts: 170

|

Post by flmlm on Jul 13, 2018 12:21:31 GMT -5

Outstanding piece of work.

Regards

Mike

|

|

|

|

Post by wbill76 on Jul 13, 2018 12:31:27 GMT -5

Thanks Mike! Trying to get this one over the finish line while I still have time left in the summer...August is when things start ramping up again for the next school year, so the window is starting to close!  No style points for the engineering design on this one that's for sure OJ! Thanks for the comments.  Enough design style to make it a repair droid on the Death Star floors!  Funny that you mention that Tobi, I'd always equated it with the Jawa sand-crawler but now I have a totally different image!  That and the beeps the little droid makes are now firmly stuck in my head.  |

|

|

|

Post by wbill76 on Jul 13, 2018 19:24:58 GMT -5

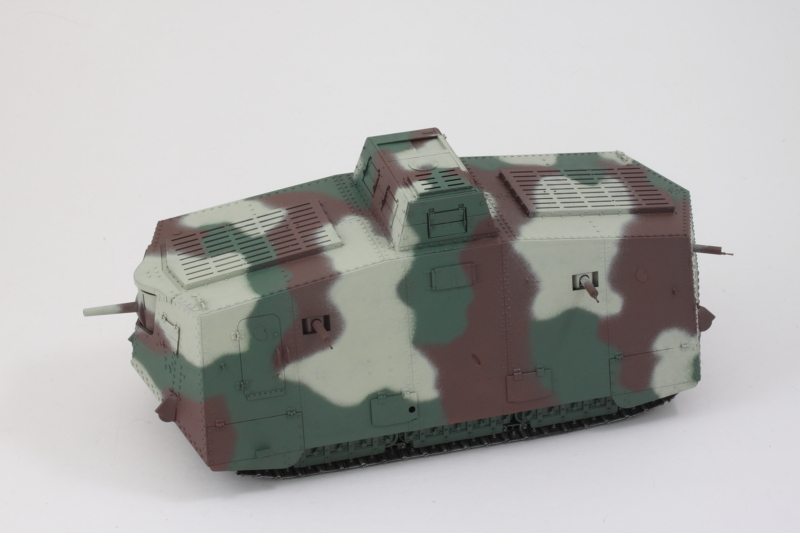

I've been working on getting the bulk of the exterior paint done over the last few days since there's a lot of surface area involved to get that accomplished. First order of business was an overall airbrushed coat of Model Master enamel Italian Dark Brown to serve as a primer/shade coat. It also had the advantage of providing a temporary stand-in for one of the camo colors as I developed the pattern.  I used the color plates in the instruction finishing guide as a rough template for creating a three-tone scheme and started with the lightest color first. I used a custom mix of Model Master Panzer Dunkelgelb and Light Gray in a 50-50 ratio and sketched the outlines of the shapes first before committing to filling them in completely. This allowed for some small adjustments/corrections as the pattern developed, very handy!  With that done, I added the green next using MM enamel Italian Olive Green. This is where the primer color helped as a temporary stand-in as I could clearly see how the 3-tone scheme was developing without having actually applied the third color yet.  Last but not least, the red-brown was airbrushed using a custom mix of 50-50 MM enamel Military Brown and Leather.   This represents a little over 5 hours of work all totaled, so a major hurdle cleared. There's still some clean-up that I need to do with some accidental overspray in a couple of spots and then apply an overall mist-coat to tie it all together before I can move on to the markings. |

|