|

|

Post by wbill76 on Aug 5, 2012 17:21:34 GMT -5

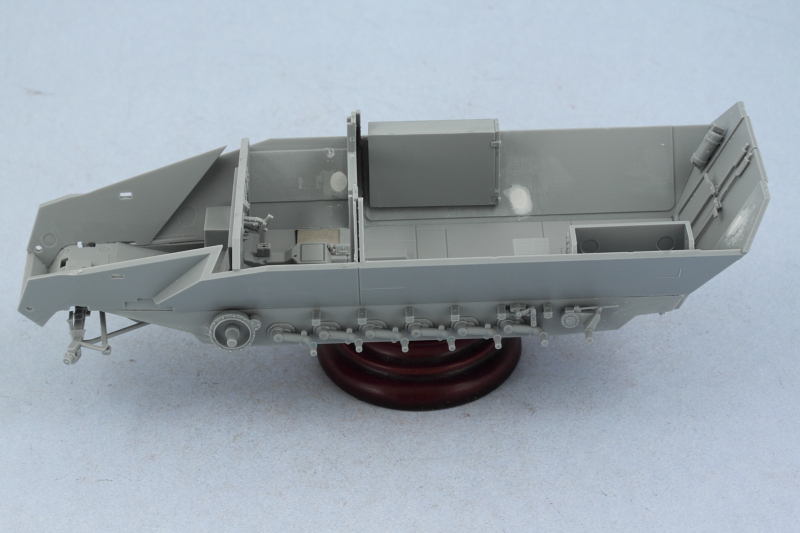

Alrighty gents, here's the latest project to hit the bench. DML's #6248 Sdkfz 251/22 Ausf D. After a careful check of production build records, the last HT to roll off the bench was in 2009 so it's time to rectify that situation!  Unlike most DML kits, the instructions for this particular kit do not begin in the usual place with the road wheels. Step 1 deals with a bunch of internal detail consisting of the transmission, the fuel tank, and other mechanical elements but all of them get hidden away by the floor panel so I skipped it and consigned the parts to the spares bin. The step does include a small sub-assembly of the shock absorbers for the final suspension arm and calls for their install in Step 1 but it's easily moved to Step 2 without any issue. Steps 2-4 deal with the lower hull suspension and the running gear elements and that's where the focus of this round of effort went. Based on past build experience of DML 251 kits, I know it's critical to get the suspension arms set at the correct height. To that end, I skipped around in the three steps and didn't follow the exact order as a result. First up was the removal of the road wheels and assembly of the mid wheel pairs while leaving the inner/outer pairs unassembled. The drive sprockets were assembled along with the front steering wheels. All the wheels received some light sanding to remove mold seams and the front steering wheels were sanded a bit heavier to simulate some road wear.  Next I installed the sprocket mounts, idler mounts, and all of the suspension arms and bump stops. The suspension arms have a little bit of wiggle to them so it's very important that they get lined up properly both vertically and horizontally so that the road wheels will sit level. Eye ball estimates are fine at this point so long as you have enough time to continue through the full step 3 installation of the front suspension as it will help ensure a level stance for the hull as well.  Speaking of which, the front wheel suspension assembly in Step 3 has an added bonus to it if you're careful with the glue and don't glue all the parts. The bonus is that the front wheels will remain steerable as well as flexible on the spring mounts laterally which helps in keeping the hull stance level as well. The trick is to not glue parts C30 and C35 (the wheel mount hubs) but instead trap them between parts C20 and C25. The second trick requires not gluing the rocker arm, C15, to C30/C35 either but use its natural snap fit to keep it in place and movable. The third and final trick is to not glue C10 to the C20/C25 assembly but instead use its join with C11 to trap the assembly and remain able to "rock" laterally.  Final trick (none of which the instructions indicate is possible by the way!) is to install the suspension into the lower hull and not apply any glue to the Y-yoke C8 at its base where it slips under the armored cover and only apply glue at the front where it attaches to the C20/C25 assembly. The end result is a fully workable and steerable front suspension.  Of course the main goal of this exercise is to end up with a suspension and running gear that sits level and does what is needed when the tracks are installed. I used poster blue tack putty to test fit the wheels and it's normal for the rear hull to have a slight angle to it as the tracks will "lift" it up and bring it level with the front when they are installed.  Next up will begin work on the compartment details. This one's off and rolling! |

|

bigjohn

Reviews member

Member since: December 2011

John Hale

Posts: 3,438

Dec 21, 2011 2:17:45 GMT -5

Dec 21, 2011 2:17:45 GMT -5

|

Post by bigjohn on Aug 5, 2012 17:38:02 GMT -5

Alright man!! I have this one in the stash, so I'll be following with great interest. Nice start on it Bill!

|

|

|

|

Post by 406 Silverado on Aug 5, 2012 17:40:30 GMT -5

Off to a good start there Bill, clean build as we have come to expect from you. I have a Panzer wrecks book with this and another HT wrecked. Been tempted to build both and place them together.

Will be following this build for sure.

|

|

|

|

Post by spud on Aug 5, 2012 18:03:45 GMT -5

Very nice Bill, i think this is one of the cooler looking ht.

|

|

|

|

Post by TRM on Aug 5, 2012 19:17:13 GMT -5

Nice start Bill!! Count me in on this!! Getting some popcorn now!! ;D

|

|

|

|

Post by bbd468 on Aug 5, 2012 19:22:36 GMT -5

AH yes Bill! Great subject. I loves me some 251 series halftracks and this has my full attention.  Gary |

|

|

|

Post by deafpanzer on Aug 5, 2012 19:43:36 GMT -5

Three years ago? Not too bad! My last HT build was probably when I was 15 years old... LOL However I do have few in my stash and I am itchin' to build one.

As usual please count me in!

|

|

|

|

Post by wbill76 on Aug 5, 2012 20:03:45 GMT -5

John, it's one of DML's popular "older" kits...how could it not be with that big ol' Pak40 strapped onto an HT!  Rob Rob, sounds like a great plan for your rusty/wrecking magic! Hope to see it come to life sooner rather than later. Spud, I agree, definitely has a mean look to it. The Pak 40 overloaded the chassis but the need for SP ATs were so strong that Hitler even declared it "one of the best designs of the war" if you can believe it. T and Gary, glad to have you along for the ride! Andy, HTs are very patient...they know they don't quite have the glamor of some of the other vehicles but they are always there for you when you want to do something a little different. I have several others in the stash although I did sell off some about a year ago to make things more manageable...at one point I had every HT kit that DML had put out of the 251 but came to the realization that I just didn't have the same "drive" to build all of them as I did when I bought them! Always a pleasure to have you along with a build.

|

|

multicam

Senior Member

Member since: January 2012

Nate

Posts: 2,039

Jan 10, 2012 14:35:41 GMT -5

Jan 10, 2012 14:35:41 GMT -5

|

Post by multicam on Aug 6, 2012 9:45:26 GMT -5

Great to see another HT in progress. And in your capable paws to boot;). Looking forward to this!

|

|

WigWag Workshop

Reviews member

Member since: May 2012

"Keep The Glue On The Styrene"

Posts: 720

May 22, 2012 7:25:45 GMT -5

May 22, 2012 7:25:45 GMT -5

|

Post by WigWag Workshop on Aug 6, 2012 10:18:58 GMT -5

Nice start, these HT are becoming my favorite builds to watch! They are truly an inspiration to watch the progress.

-Steven

|

|

|

|

Post by 406 Silverado on Aug 6, 2012 10:22:12 GMT -5

The best thing about these Dragon Ht's is that you can get them really cheap and they are loaded. The magic tracks are great and they work too. I have a Tamiya and AFV HT that will get used for that project Bill.....whenever that is.

|

|

panzerman75.

Full Member

Member since: February 2012

Posts: 292

Feb 19, 2012 1:07:13 GMT -5

Feb 19, 2012 1:07:13 GMT -5

|

Post by panzerman75. on Aug 6, 2012 10:32:30 GMT -5

Hey Bill nice start on the halftrack ill be watching this one i had one till my son thought he was godzilla lol.

Phil

|

|

|

|

Post by robbo on Aug 6, 2012 14:13:24 GMT -5

I built the AFV kit and it gave me no end of trouble, be good to see how the Dragon builds up

|

|

|

|

Post by wbill76 on Aug 6, 2012 17:55:12 GMT -5

Nate, Steven, thanks for following along! Rob, can't argue with you there! Have to be careful with the track types in some of the kits though, DML incorrectly provides an "E-Z or Magic" track set that's all steel that they label as a "later" type that was actually a dead-end attempt at saving rubber and never fully implemented as a standard track...the wear was too hard on them and the suspension vs. the "normal" type! The Tamiya and AFV kits are good wreck candidates, sounds like a plan! Phil, sorry to hear about the Godzilla treatment, I cringe thinking about it!  Robbo Robbo, I've heard others with similar experiences on the AFV kits but haven't built one myself. The DML kits build up nicely (the Ausf D kits in particular) but will be watching for potential pitfalls and report them if/when encountered! Dicky, that's true and a great example you pose for those contemplating the use of brilliant ideas before thinking things all the way through!  You have to admit though that your uncle's solution did have an certain finality in its efficiency, he never had to worry about cutting his toe nails again!

|

|

|

|

Post by 406 Silverado on Aug 6, 2012 18:08:46 GMT -5

|

|

panzerjager.

Full Member

Member since: June 2012

Posts: 204

Jun 5, 2012 21:56:23 GMT -5

Jun 5, 2012 21:56:23 GMT -5

|

Post by panzerjager. on Aug 6, 2012 22:01:42 GMT -5

I always like 251s, in either Ausf. or number. My first 1/35 model was the old Tamiya Hanomag, so I have a special love for they  Waiting for updates Darío |

|

|

|

Post by wbill76 on Aug 6, 2012 22:10:01 GMT -5

Rob, that sounds like the perfect use for them! Have the "spares" coiled up in the back fighting compartment or something similar. ;D

Dario, I have a soft spot for the 251s as well...amazing versatility in terms of capability and designs plus you can pretty much trace the progress of the war through the different variant changes, almost the same way you can do the same with the Pz IV. Glad to have you along for the ride!

|

|

Deleted

Member since: January 1970

Posts: 0

Nov 22, 2024 19:09:44 GMT -5

Nov 22, 2024 19:09:44 GMT -5

|

Post by Deleted on Aug 7, 2012 14:30:04 GMT -5

In my dim and distant past,(pre MSC)...I've nearly finished a few HT's...US and Axis,and always enjoyed them  .Now it looks like I'm in the back row watching how it should be done!! Cheers Bill  |

|

|

|

Post by 406 Silverado on Aug 7, 2012 22:32:15 GMT -5

Looking forward to Sunday for a really good update.

|

|

|

|

Post by wouter on Aug 8, 2012 8:20:26 GMT -5

another BP classic in the make ey. Nice start mate and some really nice photos as well!

Cheers

|

|

|

|

Post by 406 Silverado on Aug 8, 2012 8:22:19 GMT -5

Hey Bill, forgot to ask and don't remember if you mentioned it...but what camo scheme you going for ?? The box art scheme looks very cool.  |

|

|

|

Post by wbill76 on Aug 8, 2012 11:08:08 GMT -5

Chris, thanks for the encouragement, glad to have you along! Wouter, appreciate the comments and support as always.  Rob Rob, Box art scheme is in the lead at the moment (the instructions have limited scheme/finishing options as suggestions) and these vehicles were typically minimally marked to begin with...but I haven't yet decided if I will do it as a soft edge or hard-edged scheme. Both are possible since many of the 251/22s were done as conversion jobs on existing vehicles vs. factory purpose-built vehicles so have to give that some thought as I get closer to the paint stage.

|

|

modelfreak72

Full Member

Member since: January 2012

Why worry, each of us is wearing an unlicensed nuclear accelerator on his back.

Posts: 1,479

Jan 28, 2012 23:21:46 GMT -5

Jan 28, 2012 23:21:46 GMT -5

|

Post by modelfreak72 on Aug 9, 2012 23:51:52 GMT -5

Looking good Bill! That suspension looks alot simpler than the AFV club I got! Keeper coming!

|

|

|

|

Post by wbill76 on Aug 10, 2012 11:21:43 GMT -5

Thanks MF! Yes, the DML kits tend to be less complicated vs. the AFV kits from what I've seen and heard.

|

|

|

|

Post by wbill76 on Aug 12, 2012 16:31:46 GMT -5

Lots of progress to report as the build continues. Step 5 begins work on the interior of the fighting compartment and deals mostly with the floor and driver's area. The /22 did away with the radio operator's position because of space/access constraints due to the Pak 40 ammo bins so I removed the "hump" that is the seat mount on that side. It's molded hollow so some Lion Roar scale tread plate was used to patch the hole along with some thin sheet styrene for the side of the raised central part. The driver's seat is dry-fit only and I also installed the later type wooden crew seat for the left side. The instructions don't indicate it but two holes need to be opened up in the floor for the seat bottom to mount in the correct spot.  Step 6 assembles the driver's instrument panel. I added all the various parts called for but left off the steering wheel and gas mask container so they could be detailed separately. After painting, the dash will get the instrument face decals provided by the kit.  Step 7 is a simple step, it adds the driver's instrument panel to the floor and then adds the floor to the vehicle's lower hull completed earlier. I held off doing that just yet because the floor and side hull panels need to line up properly with each other and it's easier to achieve that by installing the three of them together vs. separately.  Speaking of the lower sides, those came next in Step 8. There are a lot of molded-on locater marks that aren't needed for this variant, so those were removed with a micro chisel and sanded smooth. Ejector marks were filled with Squadron White putty and sanded down. I also added the large ammo bin and the seat back as well as the gunner's wooden jump seat. The instructions are wrong in the placement of the side ammo bin as they point to one of the molded on marks as the correct position when the right locater marks are provided on the upper hull top...so some care is needed for the bin to end up in the right spot as both the height of the box and the position along the side matter when it comes time to add in the Pak 40 mount base in Step 15. The placement of the wooden jump seat is also critical on the other side for the same reason...so I used the blue-prints in Panzer Tracts 15-3 to help ensure I got it in the right spot and height as well.  Step 9 calls for the lower hull sides to be installed but I wanted to do that along with the rear hull plate and doors so I assembled them first as called for in Step 10. The doors were left in the closed position and putty used to fill the unused 2nd fire extinguisher slot.  Over in Step 12 the front portion of the Pak 40 mount makes an appearance but I went ahead and installed it, the floor, and the lower hull sides together in a single step to make sure everything was going to play nice and line up correctly.  Speaking of playing nice, I also decided to check the fit and alignment of the platform mount for the Pak 40. This is assembled out of multiple parts in Step 15 so that was taken care of and the mount tested along with the front bulkhead to make sure everything would fit correctly. As you can see, the fit/alignment with the other lower hull elements is tight so everything needs to be in just the right spot. I also added the smaller 5-round ammo box once the mount was glued in place so it could go in the right spot. The instructions are somewhat vague on its placement but the PT photos include a nice shot of the interior of a /22 showing how it should go. That photo also showed that DML got the placement of the hinges backward on the bin's lid so I made sure to mount it with the hinges oriented correctly.  I returned to Step 10 to assemble the front plate for the driver's visors. The kit provides the external visors as the earlier style with the ridged outer surface but the final version of the 251s had simplified these to be flat plates. That meant some careful trimming and sanding to flatten the plates down and the radio operator's plate was just a simple blank plate, so it received some putty attention to fill the back side mount point for the vision block and on the front side to fill the vision slit.  Last but not least, Step 11 deals with the upper hull and I went with the late version options featuring the single piece engine access hatch and side opening radiator access hatch. The front plate was added in and the edges blended in using a combination of liquid glue and light sanding. The top plate over the driver's area was also added but I left off the nose plate until the upper and lower hulls are joined together. Finally, I filled and sanded smooth the small mount marks for the crew jump-rail that were fitted on standard 251s but not a feature on this variant.  Next up will be assembling the Pak 40, a kit in itself! |

|

|

|

Post by spud on Aug 12, 2012 17:13:56 GMT -5

Very nice Bill, You seem to have got a fair whack of it done so far.

|

|

|

|

Post by wbill76 on Aug 12, 2012 17:20:46 GMT -5

Thanks Spud, this weekend was very productive and I kept the momentum going as far as I could to take advantage of it. Once the Pak 40 is built, paint will fly for the interior so I can get the hull put together and there won't be very much left on the exterior after that.

|

|

|

|

Post by wbill76 on Aug 12, 2012 18:14:29 GMT -5

Have to agree with you there Dicky! But then the German angled plate design on these and other APCs were cutting edge and adapted in many a post-war design to create mine-resistant vehicles and such. All I can say is lots and lots of welding was necessary to build them so I'm sure there were many a factory production line worker who cursed the designs as a result. Always a pleasure to have you comment on the progress.  |

|

|

|

Post by TRM on Aug 12, 2012 18:33:51 GMT -5

Very nice progress indeed Bill!!! Such neat and efficient work as always! Looking forward to the Pea Shooter going together!!!

|

|

|

|

Post by wbill76 on Aug 13, 2012 12:52:42 GMT -5

Thanks T! The Pak 40 is a nice little sub-kit, comes with a turned aluminum barrel and other options/goodies that make it a nice addition.

|

|

?

?