Post by fhvn4d on Aug 7, 2016 16:00:01 GMT -5

Little late out of the gate on this one, because frankly I didnt expect much from the build. It started out as a quick build for TRM to paint, but it has manifested itself into a true experiment in outside my comfort zone building. It will probably follow along with some painting and weathering under the guidance of the two musketeers, but I am actually learning along the way... and input is welcome!

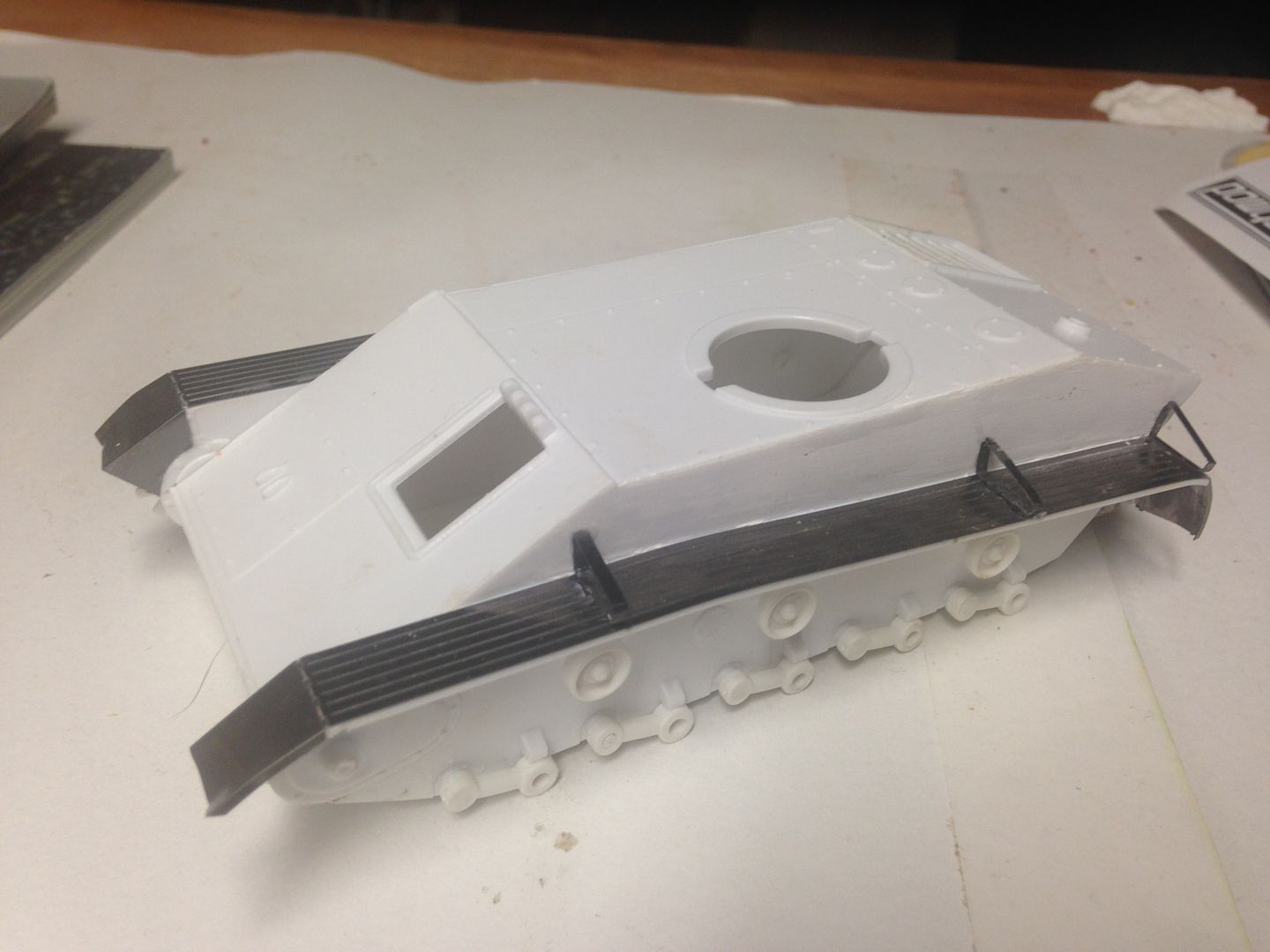

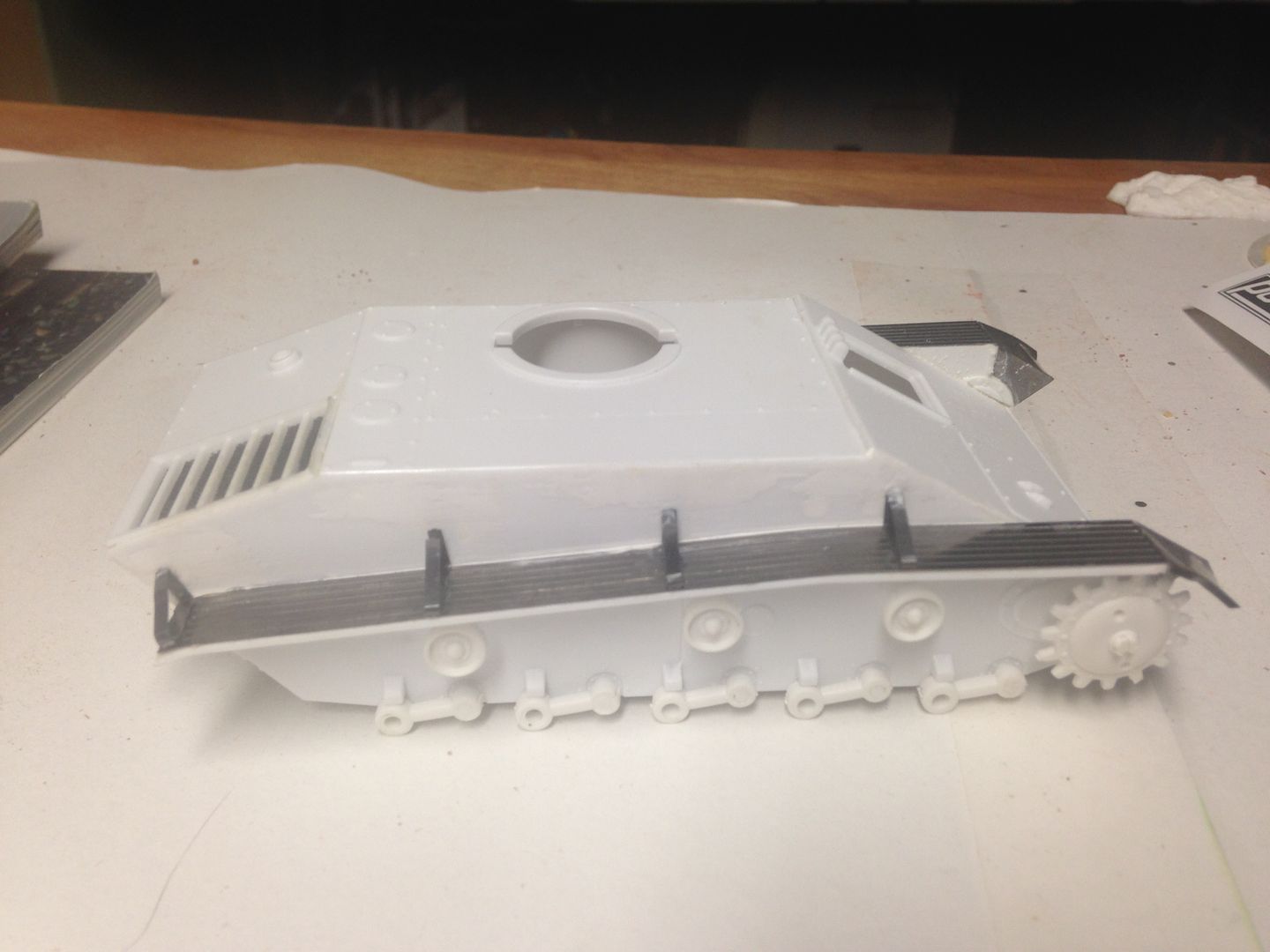

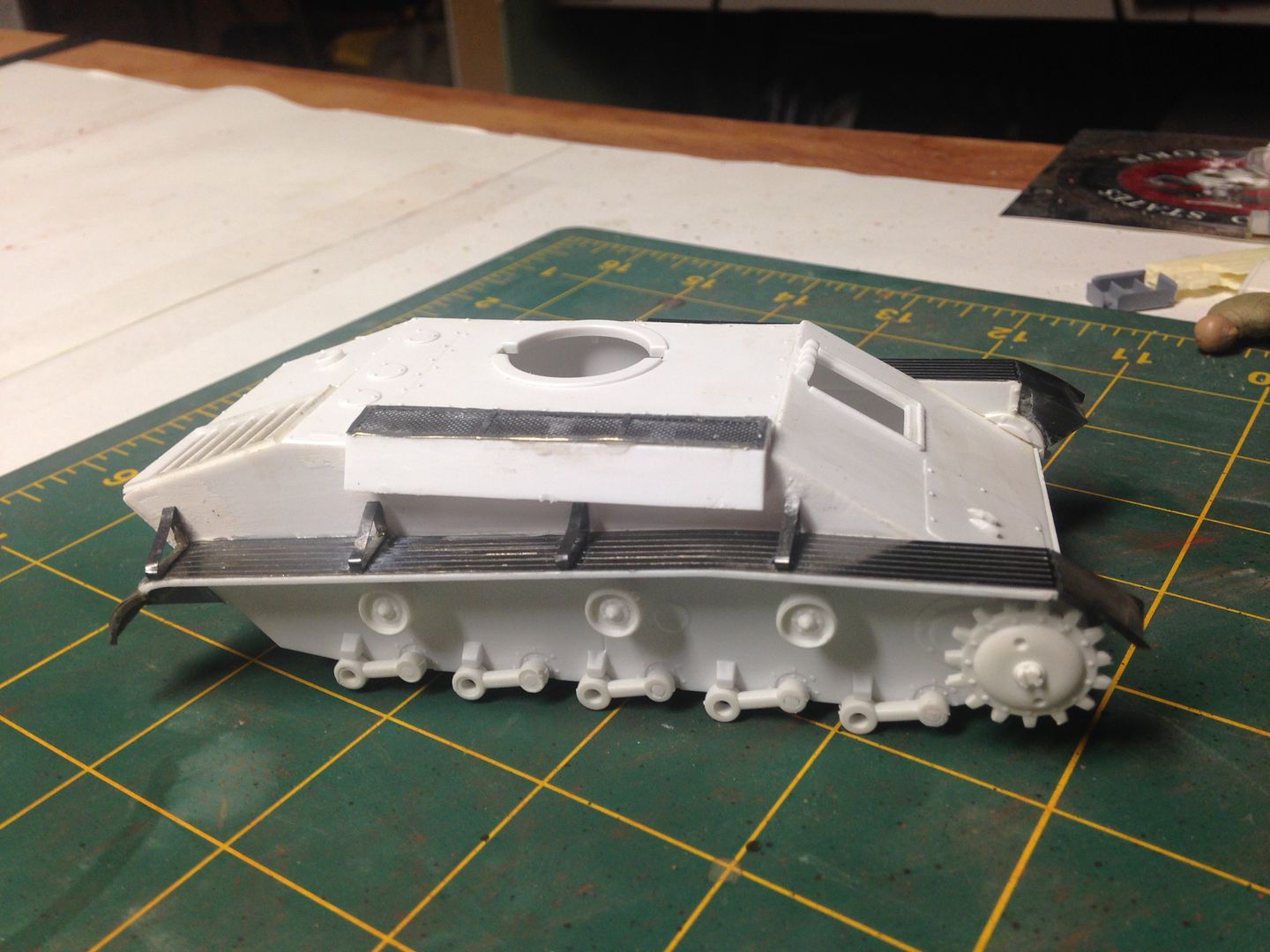

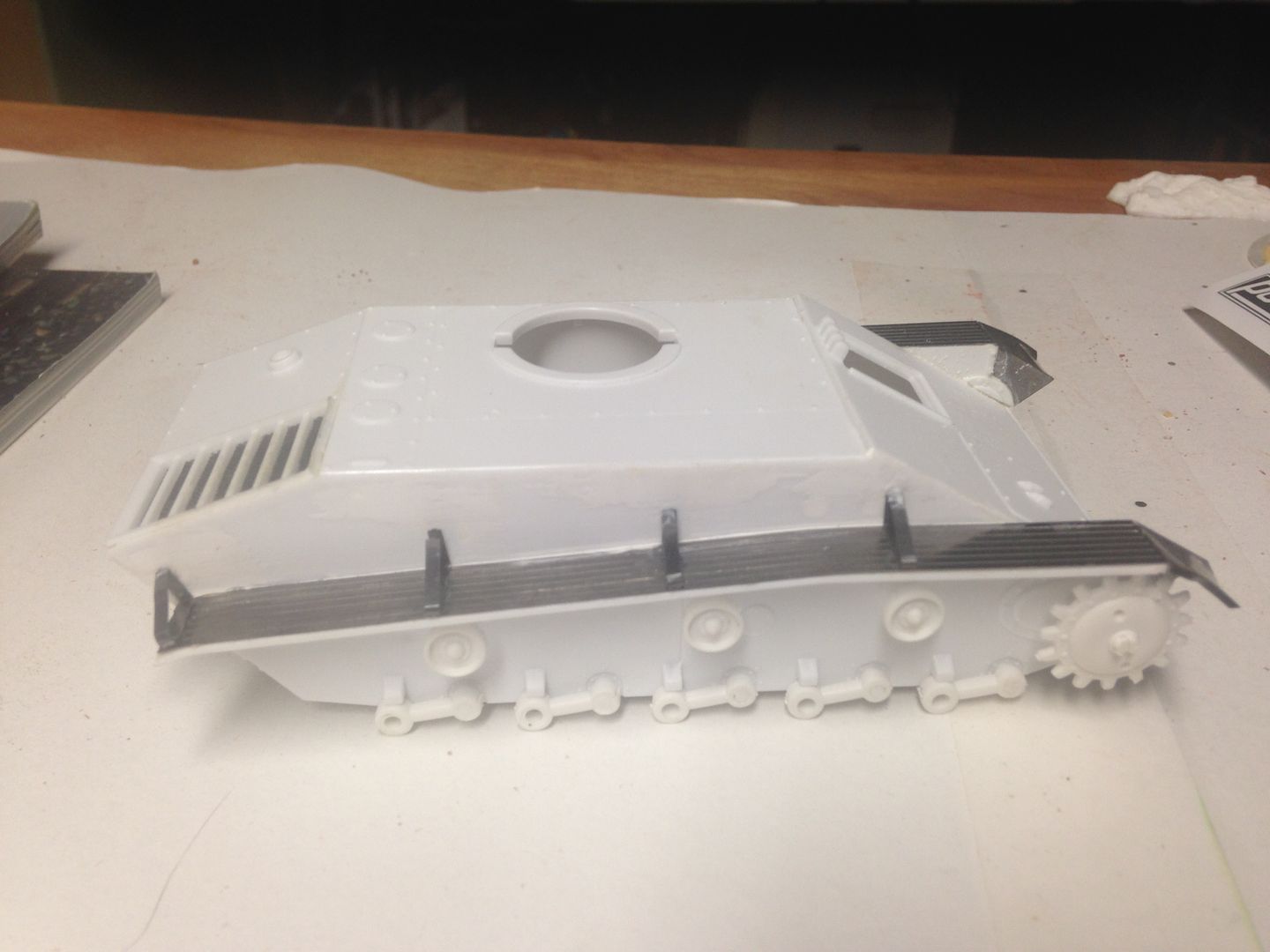

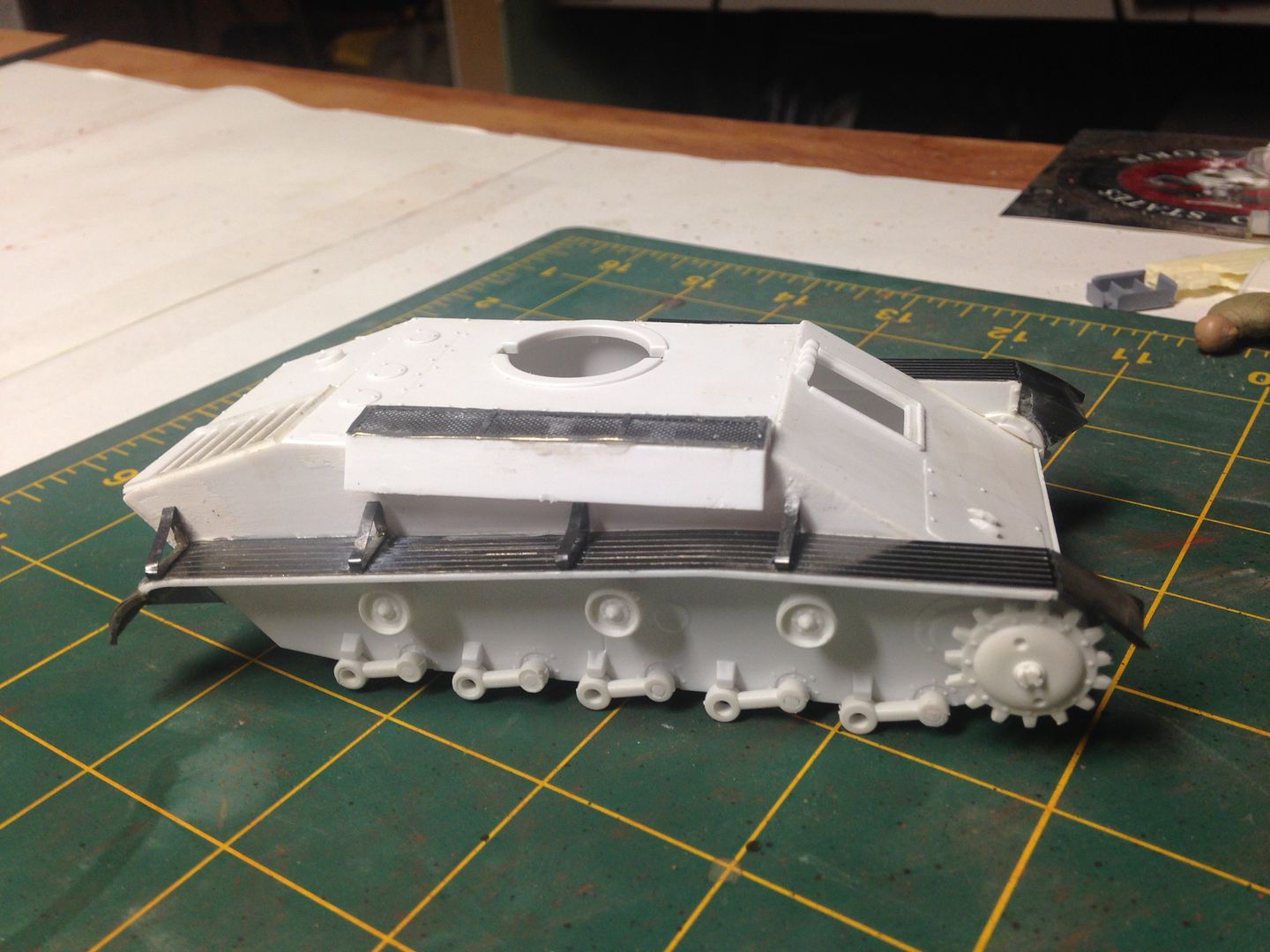

So it started out last year at Armorcon when I got this Techmod T-70 and Eduard PE set as a raffle prize. I am not one for Pre Vietnam era anything (although that is developing nicely now LOL) so I had planned on a trade/sale. Then it came to me to slap this thing together and offer it up to someone who might need sacrificial lambs for painting events.... Que Rob and Todd. So, I start just fitting and gluing and doing minimal sanding, and started to think about how much fun it was to just slap something together right by the directions and not lose my mind over seams or gaps. Then this photo etch set starts staring me down... you see, I have VERY LIMITED exposure to PE. Like, almost none. But there it is, daring me to try some slapping that on.... so... here goes!

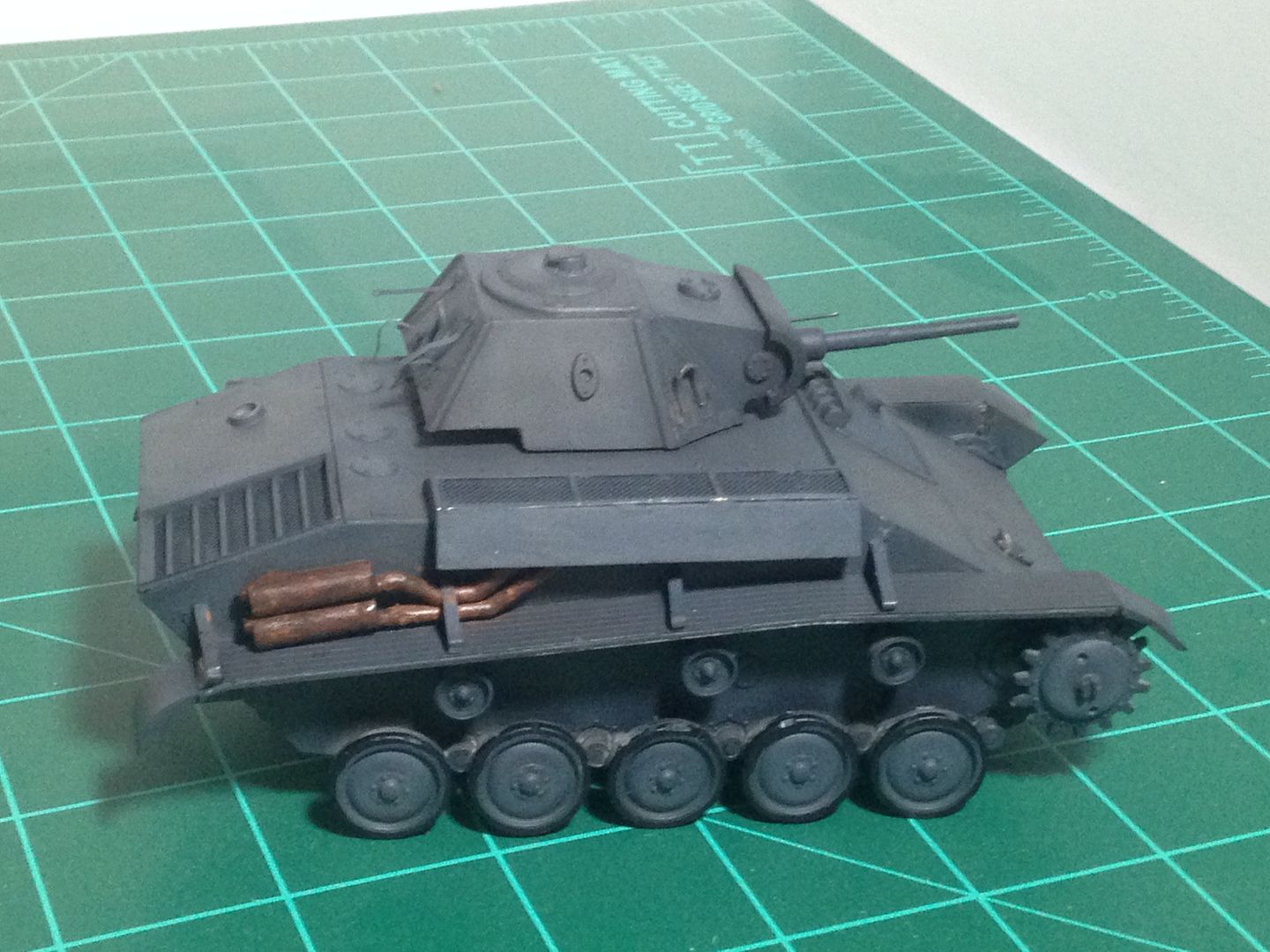

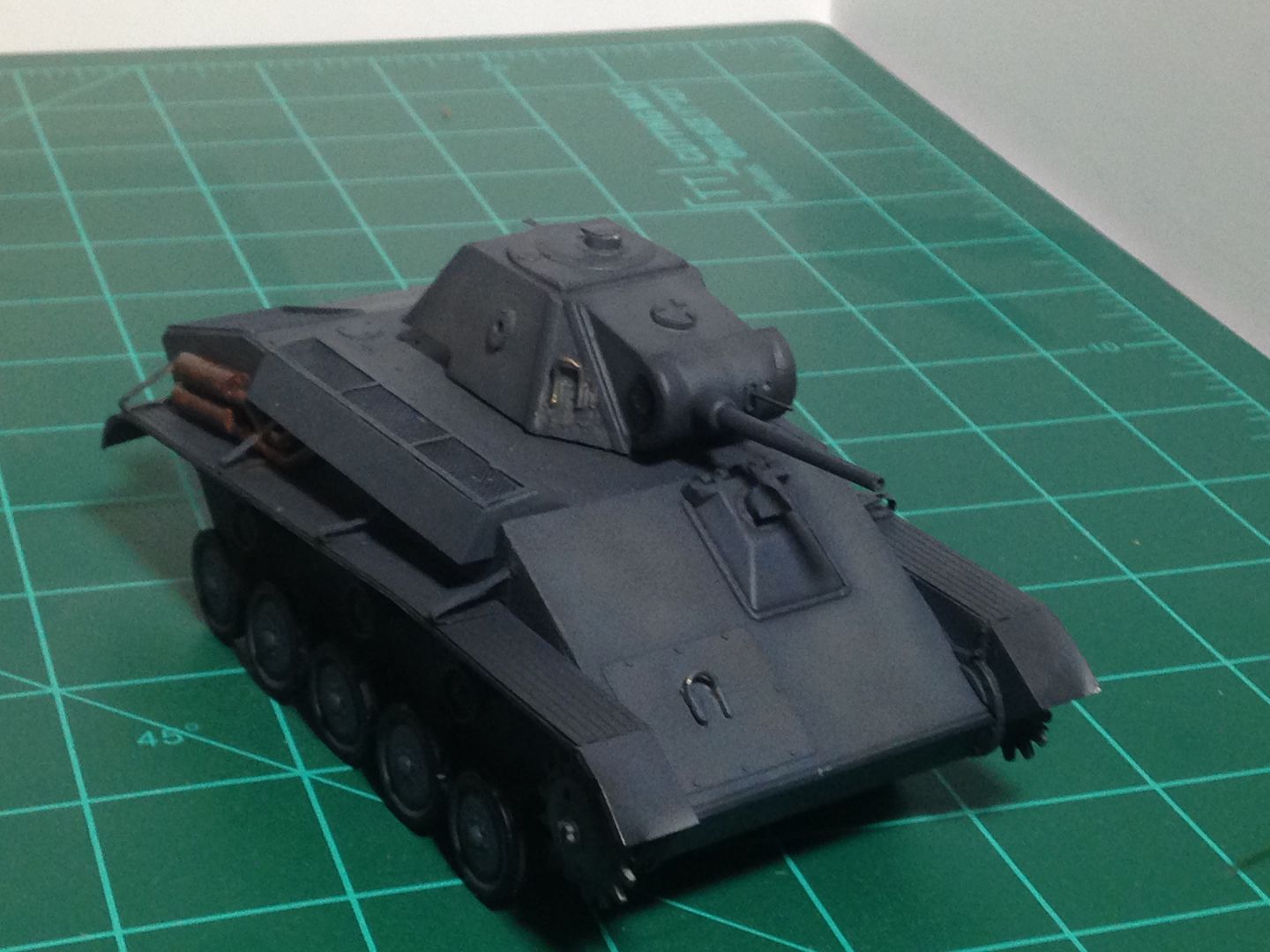

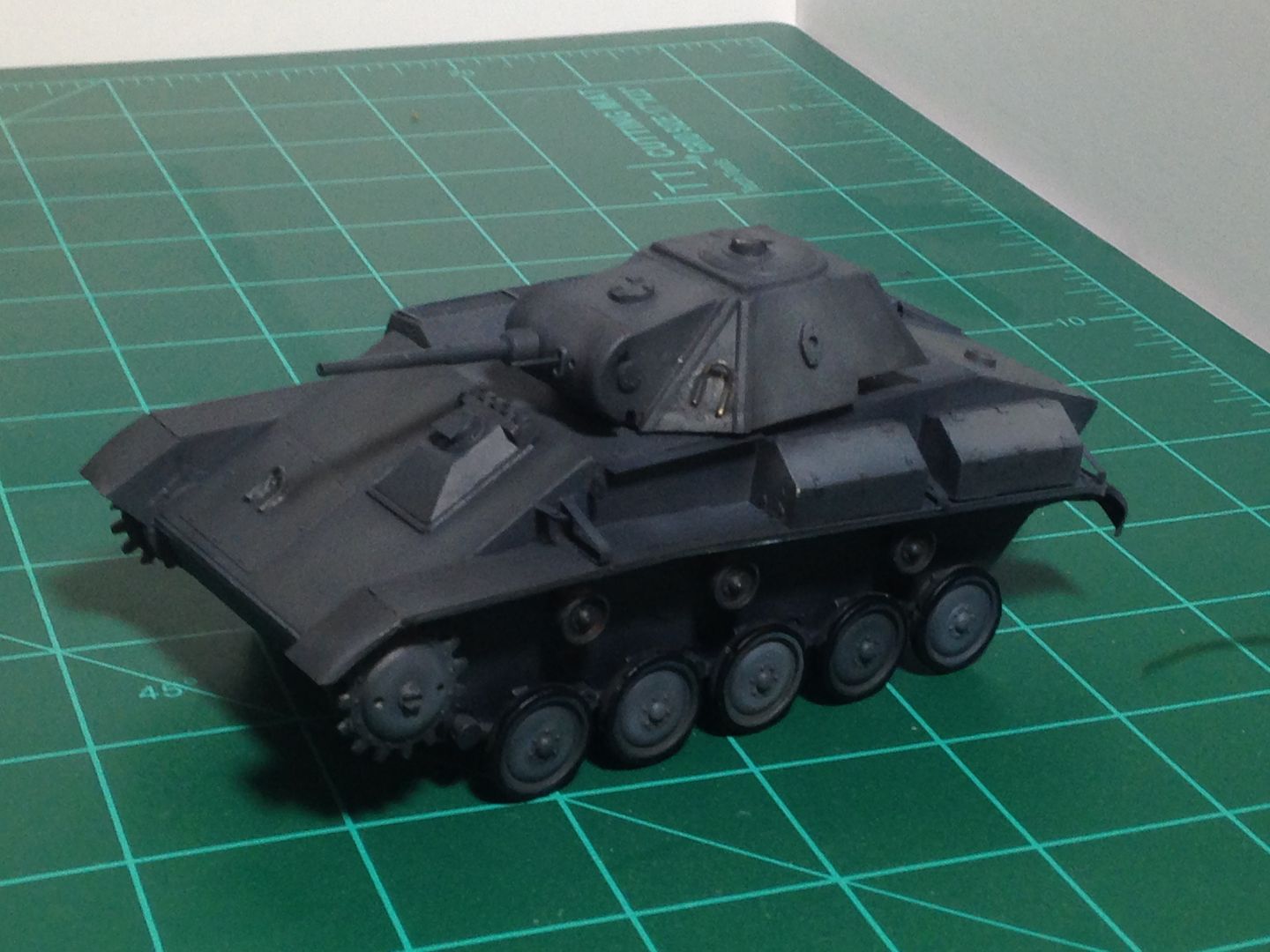

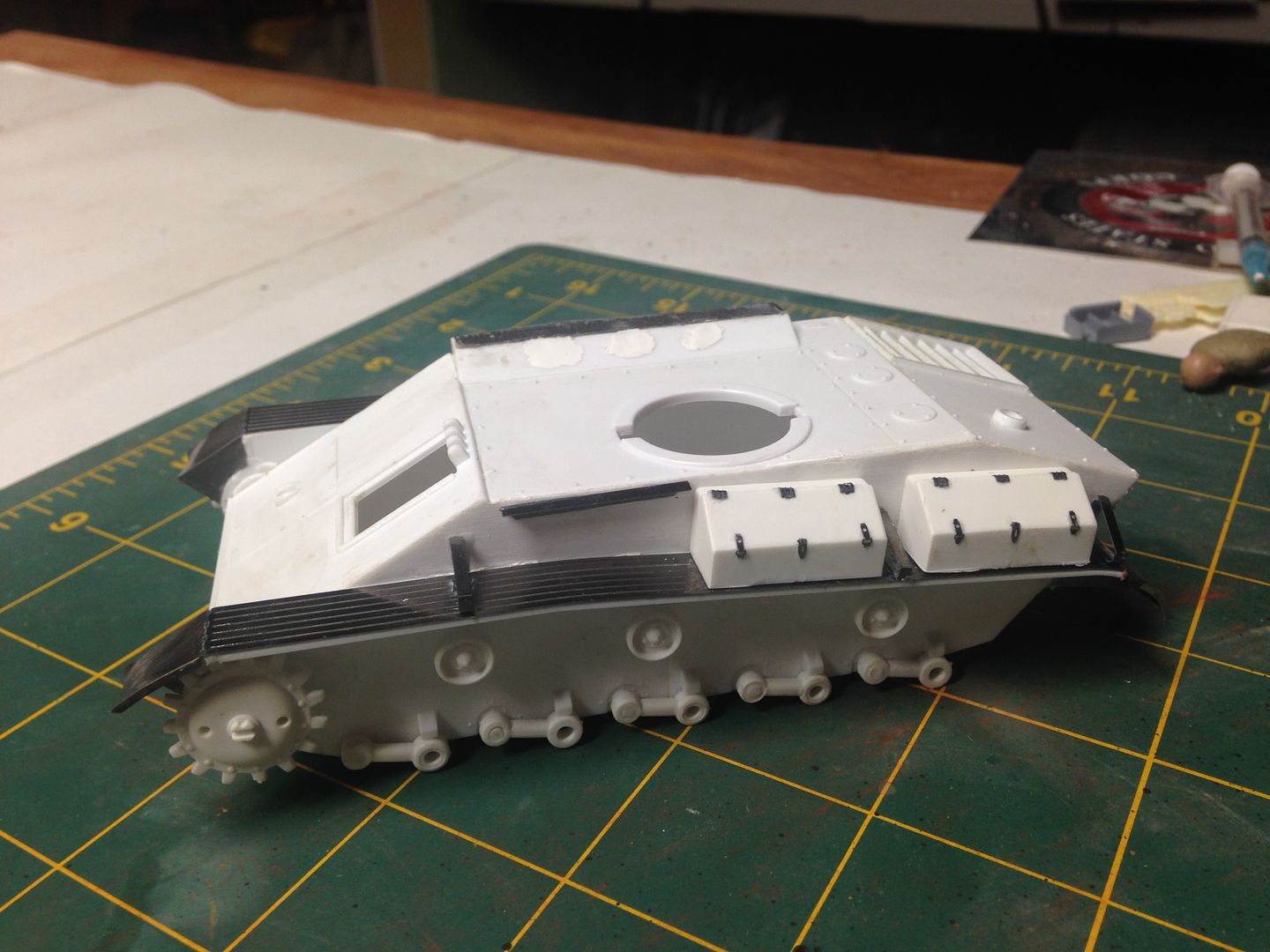

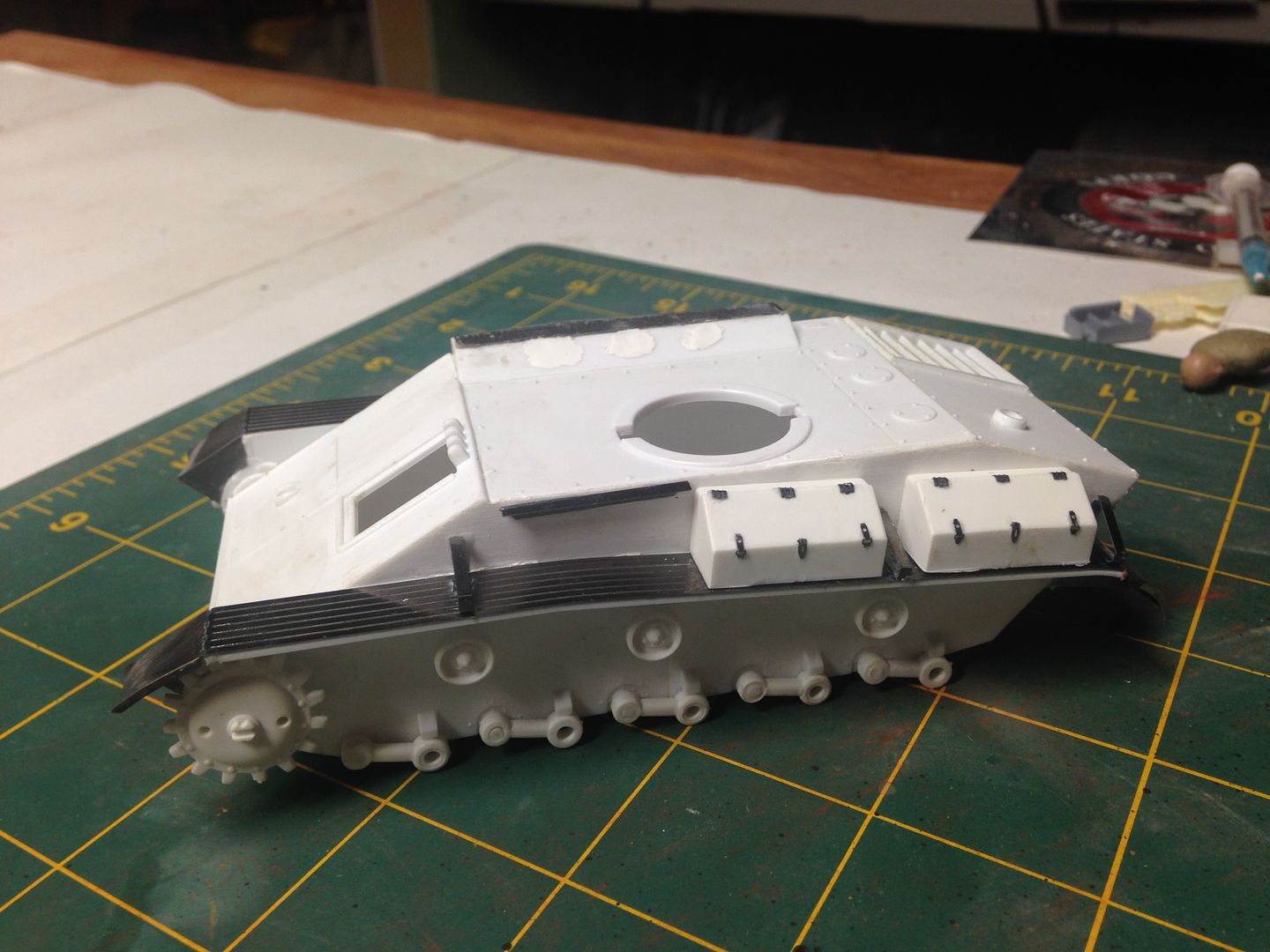

it had originally started out to stop here and just go with the plastic, but then I saw a video on how to do fine soldering of PE parts, and I had to try it. I was really pleased with the results on the fenders and the metal brackets that I used it on ( I had initially used superglue and was NOT pleased). Once I used the suggestions in the video, which including making shavings of the solder and being very careful with flux placement, these were the results and I have found a new "Must incorporate" technique with PE work.

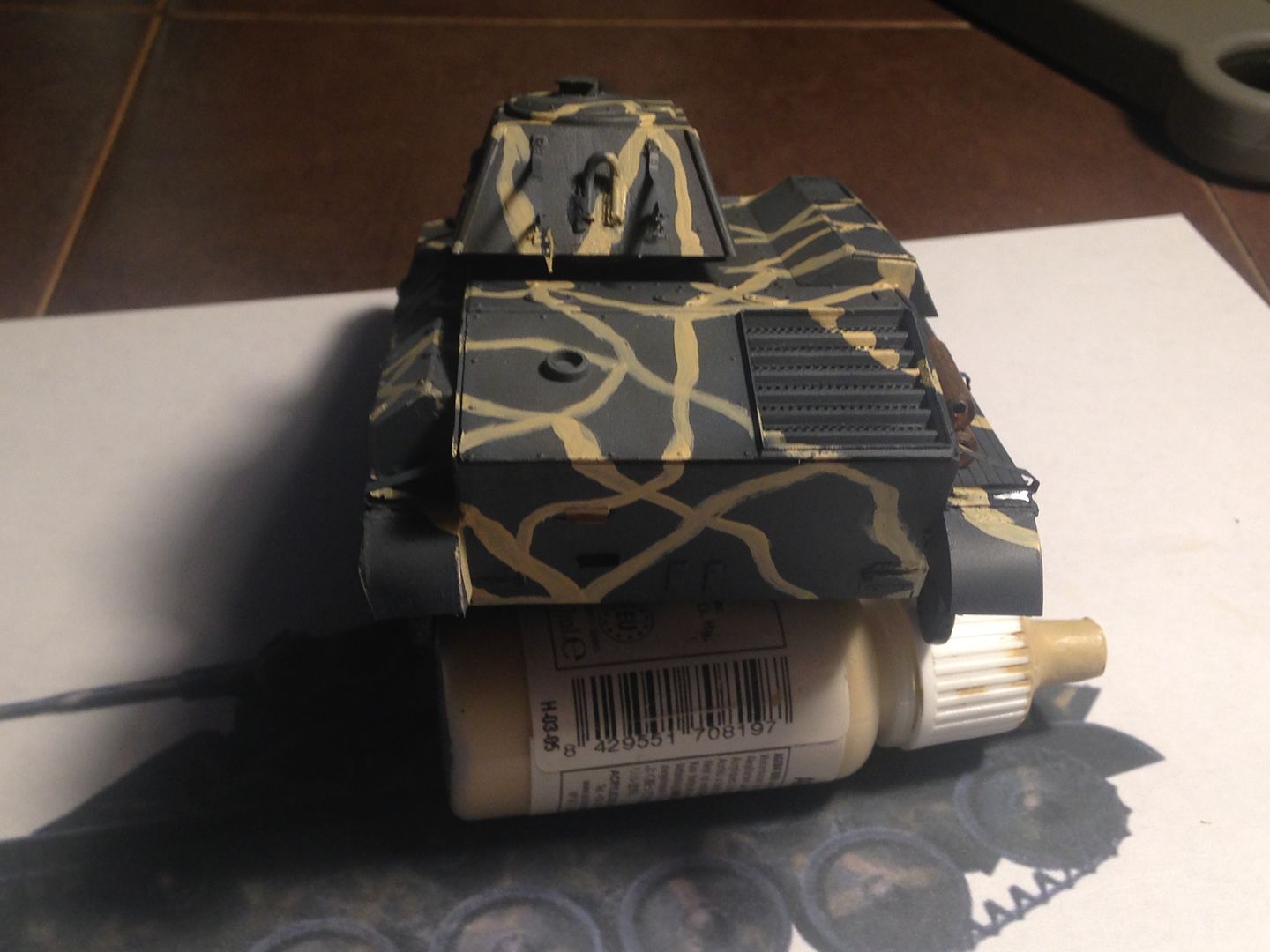

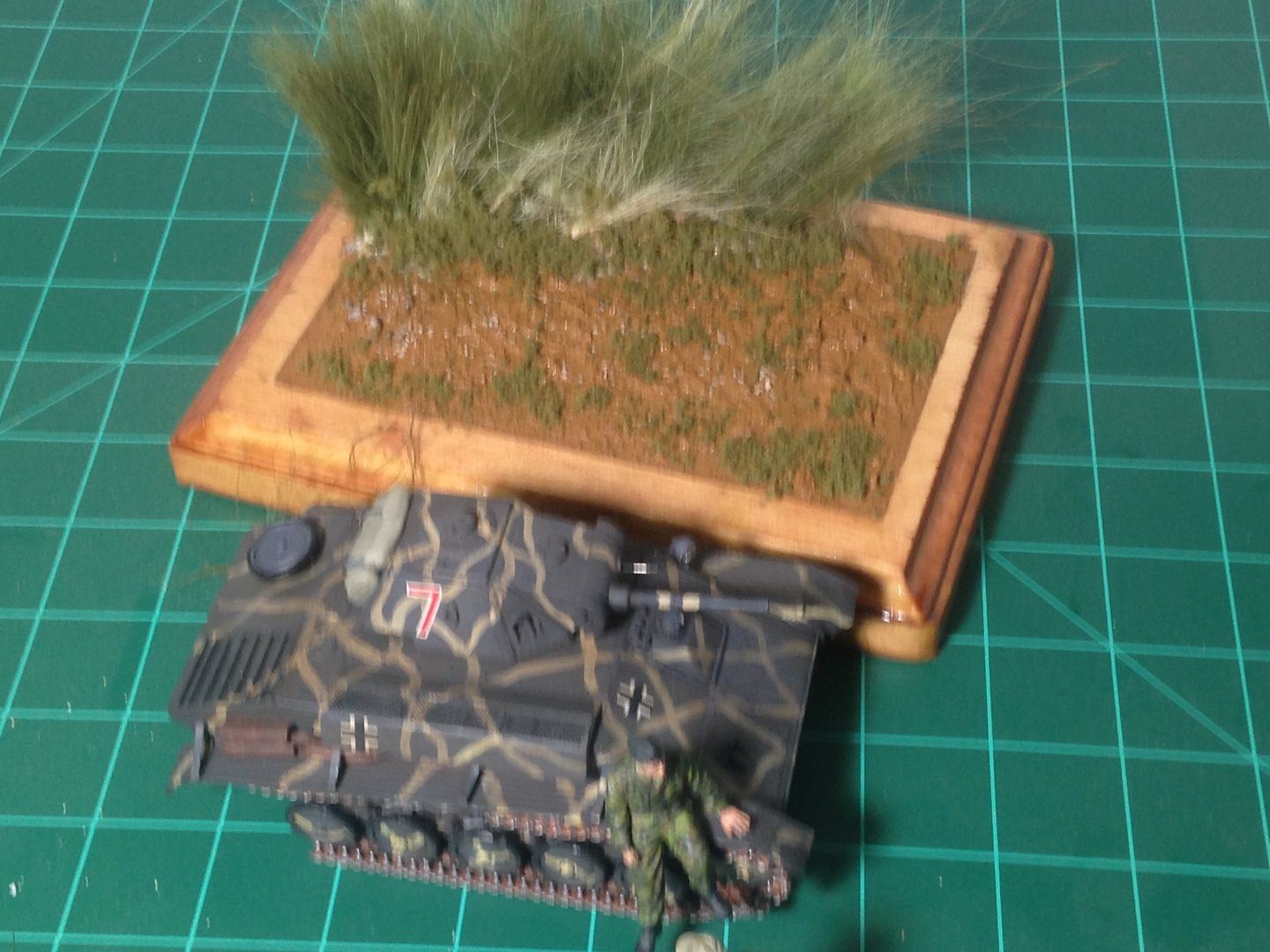

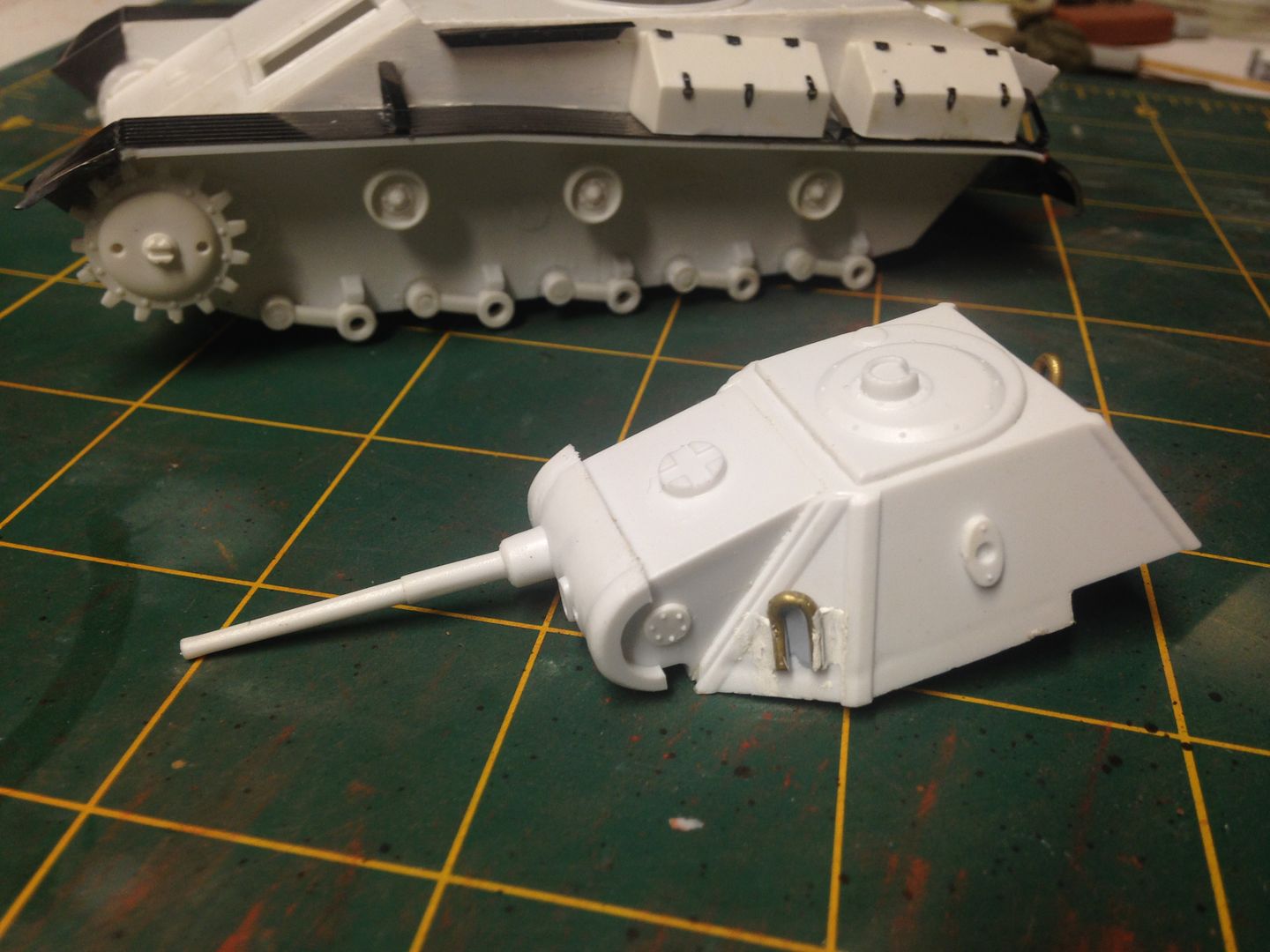

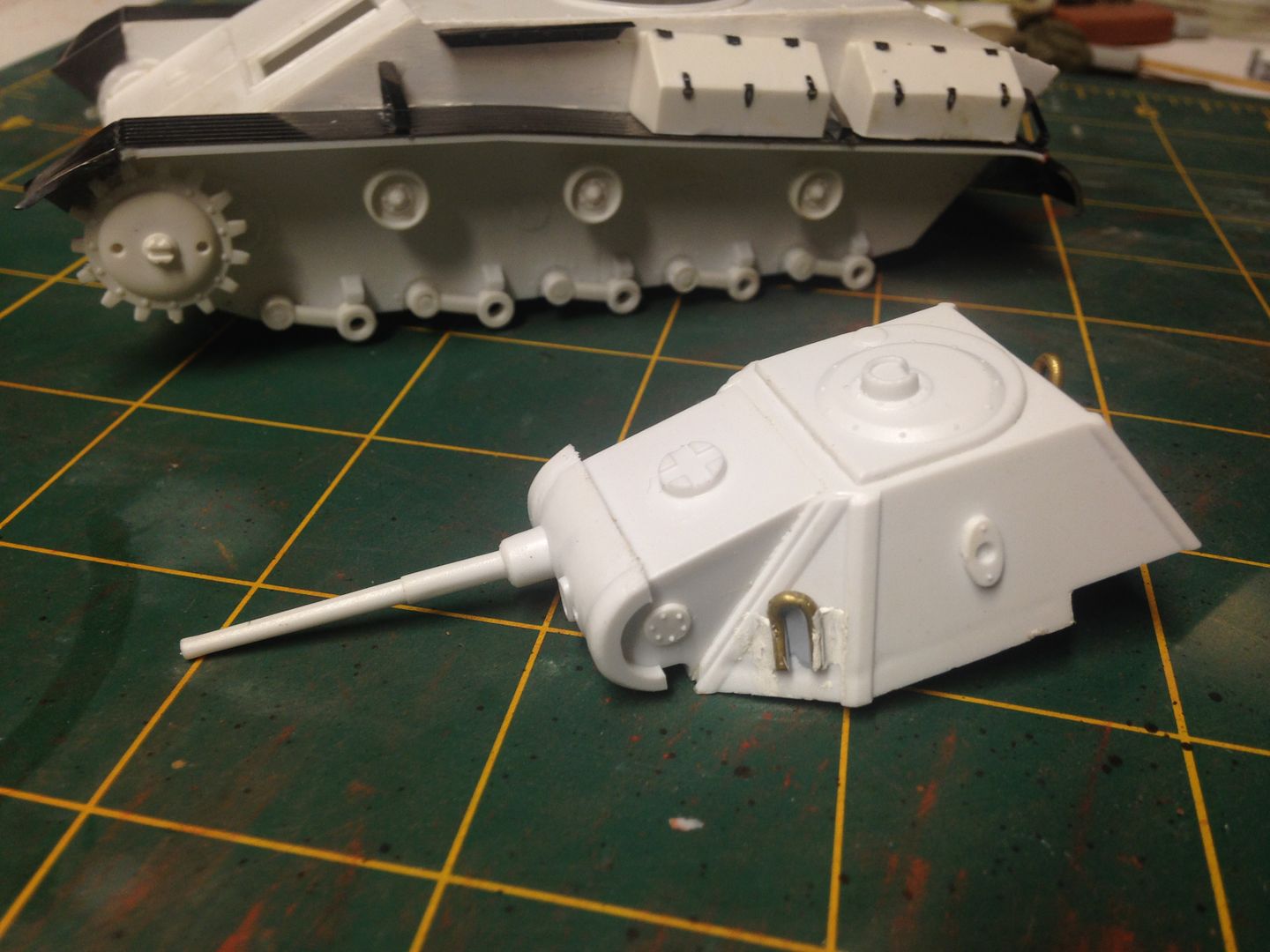

The last few photos are where I am at today. The turret has received some home made lifting eyes with an attempt to replicate weld lines, the barrel was bored out on the main gun, and the coax was simulated with a hypodermic needle (Being a paramedic has its advantages).

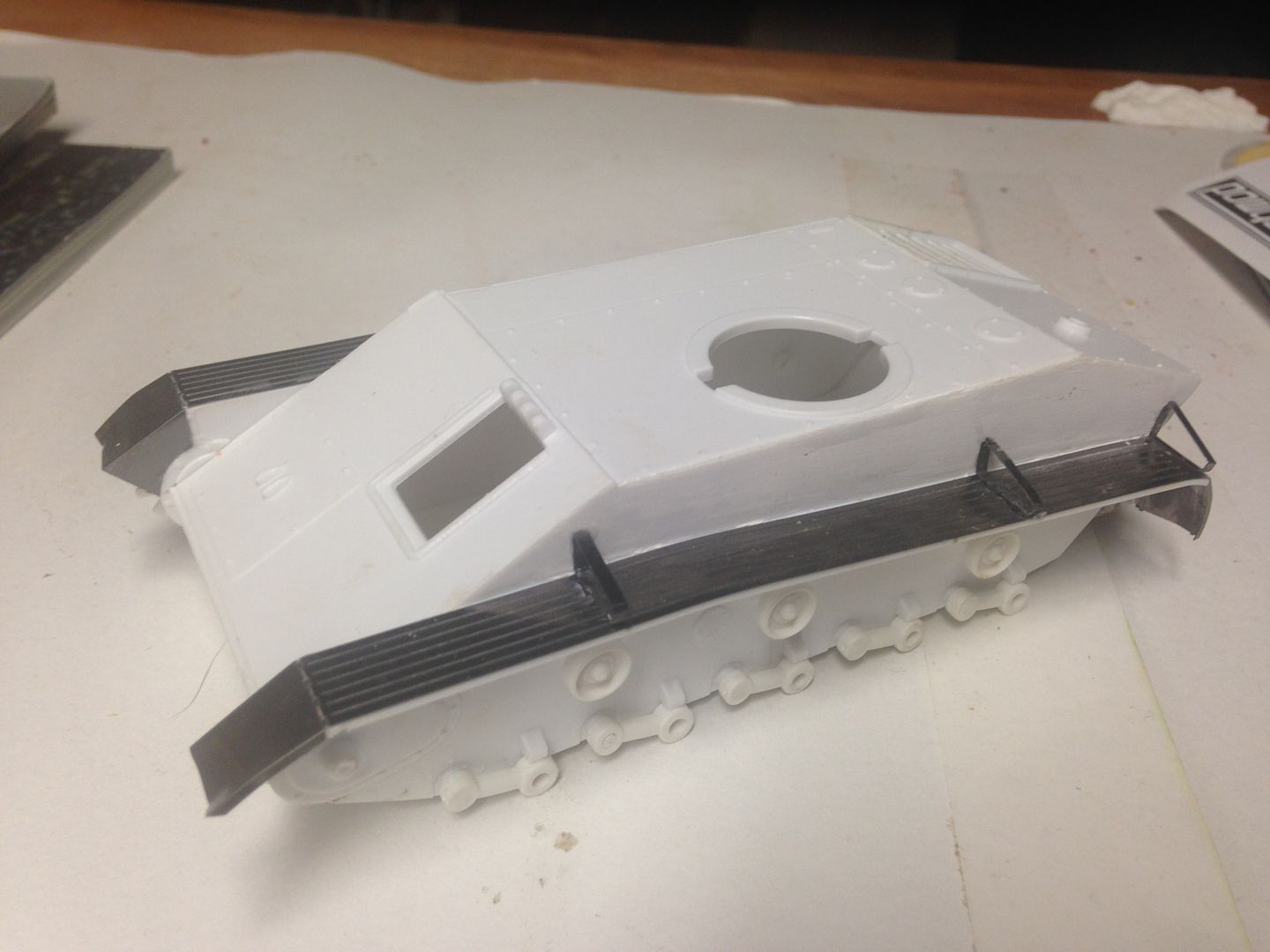

The big stumbling block that I am still dealing with, is what glue is right when? I have come to the conclusion that superglue is not always the right tool for this job, and I am experimenting with clear pva glue, and maybe some 5 minute epoxy in the near future. I always seem to fall back on the CA glue and I never fail to make a mess when I do. Smaller parts that I THOUGHT were well attached have come off and through pure luck (scratched my private parts and lo and behold there was the hinge that I had lost into my shorts!) I have been able to re-install all but one piece. Definitely open to hear what others do to get the parts down just right without seriously overloading with the superglue! Hope to finish it up this week and start slapping some color on. (My goal is for this kit to get me out of the beginner field in AMPS and officially get gold and put myself into intermediate!)

So it started out last year at Armorcon when I got this Techmod T-70 and Eduard PE set as a raffle prize. I am not one for Pre Vietnam era anything (although that is developing nicely now LOL) so I had planned on a trade/sale. Then it came to me to slap this thing together and offer it up to someone who might need sacrificial lambs for painting events.... Que Rob and Todd. So, I start just fitting and gluing and doing minimal sanding, and started to think about how much fun it was to just slap something together right by the directions and not lose my mind over seams or gaps. Then this photo etch set starts staring me down... you see, I have VERY LIMITED exposure to PE. Like, almost none. But there it is, daring me to try some slapping that on.... so... here goes!

it had originally started out to stop here and just go with the plastic, but then I saw a video on how to do fine soldering of PE parts, and I had to try it. I was really pleased with the results on the fenders and the metal brackets that I used it on ( I had initially used superglue and was NOT pleased). Once I used the suggestions in the video, which including making shavings of the solder and being very careful with flux placement, these were the results and I have found a new "Must incorporate" technique with PE work.

The last few photos are where I am at today. The turret has received some home made lifting eyes with an attempt to replicate weld lines, the barrel was bored out on the main gun, and the coax was simulated with a hypodermic needle (Being a paramedic has its advantages).

The big stumbling block that I am still dealing with, is what glue is right when? I have come to the conclusion that superglue is not always the right tool for this job, and I am experimenting with clear pva glue, and maybe some 5 minute epoxy in the near future. I always seem to fall back on the CA glue and I never fail to make a mess when I do. Smaller parts that I THOUGHT were well attached have come off and through pure luck (scratched my private parts and lo and behold there was the hinge that I had lost into my shorts!) I have been able to re-install all but one piece. Definitely open to hear what others do to get the parts down just right without seriously overloading with the superglue! Hope to finish it up this week and start slapping some color on. (My goal is for this kit to get me out of the beginner field in AMPS and officially get gold and put myself into intermediate!)