atomicholiday

Full Member

Member since: September 2023

Posts: 411

Sept 4, 2023 8:25:11 GMT -5

Sept 4, 2023 8:25:11 GMT -5

|

Post by atomicholiday on Feb 13, 2024 17:44:24 GMT -5

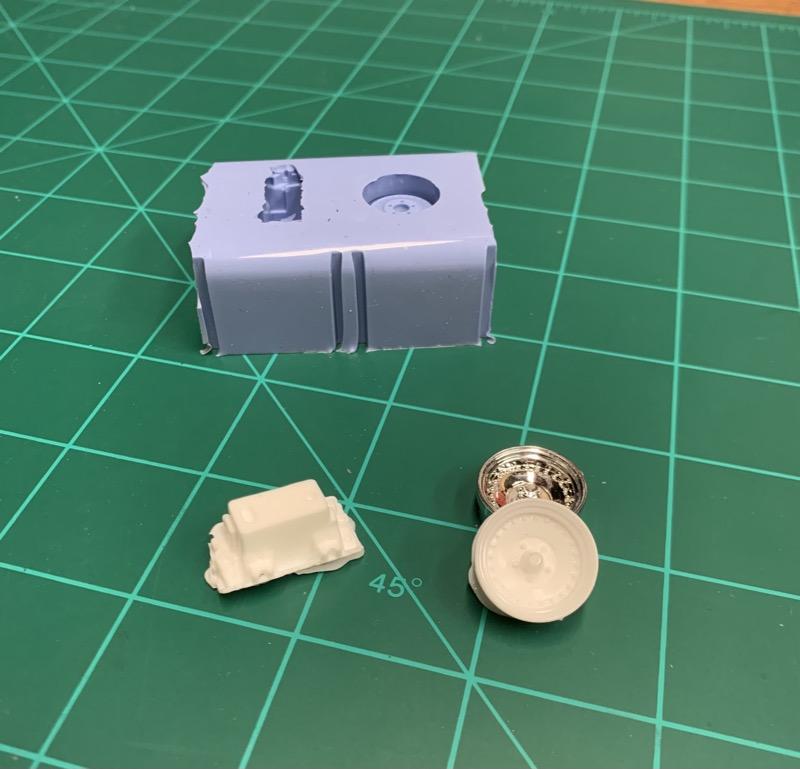

Well technically my second attempt I guess. I bought a kit on clearance from Hobby Lobby about a year ago, but it was past it's sell-by date. The silicone mold never did set up. Fast forward to last weekend. I got a starter kit from Smooth-on and gave it a shot. The mold itself turned out really good I think. No bubbles at all. Then last night I cast these two parts. I was expecting it to be a fail, and being a first attempt, I wasn't too worried about it. It was more just "let's see what happens". To my surprise, the parts came out pretty darn good! I got one small bubble in each part and that's it. I can totally live with that for a first shot. I'm pretty excited about this, as I've got some older parts I was to use on newer kits. Next up is a set of five-slot rims from an old Monogram kt that I've been itching to copy. Anybody else here do their own casting?  |

|

|

|

Post by project510 on Feb 13, 2024 17:47:38 GMT -5

Once you perfect this you are going to get a ton of requests! Good luck! Cool stuff!

|

|

|

|

Post by kyledehart5 on Feb 13, 2024 19:59:03 GMT -5

Those look great!! I have recently acquired my own mold making set with the intentions of trying to copy some older parts myself but haven’t tried it yet.

|

|

|

|

Post by Tobi on Feb 14, 2024 1:29:15 GMT -5

I did casting myself, but constantly had to fight bubbles, so ceased to do it, but want to pick it up again after I saw that you get better results under vacuum.

So my plan is to buy a small kitchen vacuum pump and accompanying container for my next try.

A friend of mine did experiments with first brushing a layer of resin into the form and then casting it fully, with good results, but this didn't work for me either back then.

Your first samples do look very good!

|

|

jeaton01

Full Member

Sept '23 Showcased Model Awarded

Sept '23 Showcased Model Awarded

Member since: October 2013

Posts: 1,267

|

Post by jeaton01 on Feb 14, 2024 1:58:47 GMT -5

Vacuum is good for de-airing the silicone, but I think pressure might be better for resin cast parts. Being in a warm enough area is important, and keeping moisture out of the resin is also important. I think when resin components get old and don't work well it's actually moisture that is the issue as well as age. The bubbles in resin are less of an issue under pressure as the air is compressed.

I think some of the professional resin casting people are using better resin that we can find as hobbyists.

|

|

|

|

Post by Tobi on Feb 14, 2024 4:20:36 GMT -5

Vacuum is good for de-airing the silicone, but I think pressure might be better for resin cast parts. Being in a warm enough area is important, and keeping moisture out of the resin is also important. I think when resin components get old and don't work well it's actually moisture that is the issue as well as age. The bubbles in resin are less of an issue under pressure as the air is compressed. I think some of the professional resin casting people are using better resin that we can find as hobbyists. Some years ago I saw a walk around video taken in the workshop of MR Modelle here in Germany, a professional resin caster for armor AM stuff. There they showed how they cure the resin in a vacuum box, saying this would suck out the bubbles. |

|

atomicholiday

Full Member

Member since: September 2023

Posts: 411

Sept 4, 2023 8:25:11 GMT -5

Sept 4, 2023 8:25:11 GMT -5

|

Post by atomicholiday on Feb 14, 2024 6:55:29 GMT -5

Once you perfect this you are going to get a ton of requests! Good luck! Cool stuff! Just send show me the money!  Really though, I don't intend to get into business with it. It's just to make some parts here and there. Stuff that's out of print (like those old Monogram wheels). But that being said, once I get more confident, I'd help a brother out if they needed something. Those look great!! I have recently acquired my own mold making set with the intentions of trying to copy some older parts myself but haven’t tried it yet. Cool! Looking forward to seeing what you do with it. My advice would be watch as many videos on the subject as you can find. A good starting point to give you an idea as a beginner is one I found by Muscle Car Modeler on youtube. Then read all the directions carefully. Finally have everything ready to go before you even open the first bottle. I did casting myself, but constantly had to fight bubbles, so ceased to do it, but want to pick it up again after I saw that you get better results under vacuum. So my plan is to buy a small kitchen vacuum pump and accompanying container for my next try. A friend of mine did experiments with first brushing a layer of resin into the form and then casting it fully, with good results, but this didn't work for me either back then. Your first samples do look very good! Yup, I saw several videos with both vacuum and pressure. I think that's the way to go if you want get really good results and are planning to do this a lot. I may get to that point at some time, but for now, this will have to do. I will say, casting seems like it could become a rabbit hole if you're not careful. I think some of the professional resin casting people are using better resin that we can find as hobbyists. I've wondered about that too. It would be really interesting to see what those guys are using. |

|

brandonk

Full Member

Jan '24 Showcased Model Awarded

Jan '24 Showcased Model Awarded

Member since: May 2023

Posts: 1,252

May 14, 2023 13:45:45 GMT -5

May 14, 2023 13:45:45 GMT -5

|

Post by brandonk on Feb 14, 2024 10:22:52 GMT -5

I just got myself a basic silicone mold setup so I can try to cast some clear UV resin parts like headlights for car and whatnot. I'm going to try and replace chrome lights with clear resin. Gonna be learning curve for sure. Then I'll likely go more into full on resin castings and pressure pots.

|

|

|

|

Post by Steve Zuleski on Feb 14, 2024 11:56:18 GMT -5

Excellent!

|

|

jeaton01

Full Member

Sept '23 Showcased Model Awarded

Sept '23 Showcased Model Awarded

Member since: October 2013

Posts: 1,267

|

Post by jeaton01 on Feb 14, 2024 14:17:17 GMT -5

I have done clear resin and the material I used took a long time to harden. I used it to make windows in an airliner by pouring the resin into each window and sanding them flush after it had cured for a week.  |

|

atomicholiday

Full Member

Member since: September 2023

Posts: 411

Sept 4, 2023 8:25:11 GMT -5

Sept 4, 2023 8:25:11 GMT -5

|

Post by atomicholiday on Feb 16, 2024 14:34:05 GMT -5

I have done clear resin and the material I used took a long time to harden. I used it to make windows in an airliner by pouring the resin into each window and sanding them flush after it had cured for a week.  That looks terrific! I was wondering about clear resin. I have a couple of kits that are missing a few clear parts. Taillights and headlight covers. That sort of thing. |

|