|

|

Post by deafpanzer on Aug 19, 2014 19:30:55 GMT -5

DAMN! Fantastic PE work!!! And you are not helping me at all believe me! I have USS Indy sitting on my bench right now...

|

|

|

|

Post by TRM on Aug 19, 2014 19:43:43 GMT -5

I am loving all the little details falling into place now!!

|

|

|

|

Post by wbill76 on Aug 20, 2014 11:29:22 GMT -5

Thanks Leon! Each of those cable stays for the funnels is a separate piece...so four per side. That was a lot of fun getting them lined up properly I can tell you.  Andy Andy, you know you want to get started on the Indy...can't have her sitting in dry-dock forever you know!  T T, lots of little tiny bits still to come, that's for sure!  |

|

|

|

Post by TRM on Aug 20, 2014 17:30:37 GMT -5

T, lots of little tiny bits still to come, that's for sure!  Feeling your pain right now...LOL!! Just finish the bulk of some priming!! 85% of the tinniest are done!!  |

|

|

|

Post by wbill76 on Aug 20, 2014 17:35:02 GMT -5

They say the devil's in the details...well today the devil tasked me with working on the searchlights. Since a few of these go on the super deck and the boat deck, I decided it was as good a time as any to tackle them all and get them ready for painting along with the other details. The kit supplies you with 14 but only 13 are needed. I went ahead and prepped all 14 just to have a spare since the Eduard PE set includes 14 bezels as well. First up was drilling out the faces of the lights. This was done with a pin vise by hand while the lights were still on the sprues. This made it much easier to handle them and control the drill bit vs. trying to do it with them off the sprues.  Once that was taken care of, they were removed from the sprues and cleaned up where needed. The Eduard bezel faces were added using liquid glue and a spit-moistened toothpick to help in the pick-up-and-placement of each little bezel.  Once painted, these will get further detailed for the reflective surfaces and what not. |

|

|

|

Post by TRM on Aug 20, 2014 17:39:40 GMT -5

That is some nice detailing there Bill!  |

|

|

|

Post by wbill76 on Aug 20, 2014 17:55:04 GMT -5

Thanks T! Nothing to rival the pom-poms on your Roberts but close enough I reckon.  |

|

|

|

Post by deafpanzer on Aug 21, 2014 9:38:25 GMT -5

Good thinking drilling while they are still attached to the sprue... thanks for the tip!!! Looking awesome!

|

|

|

|

Post by 406 Silverado on Aug 21, 2014 9:40:54 GMT -5

Some fantastic work Bill. Not so easy when there are a ton of teeny tiny parts.

|

|

Foenetik

Full Member

November '24 Showcased Model Awarded

November '24 Showcased Model Awarded

Member since: March 2014

Posts: 609

|

Post by Foenetik on Aug 21, 2014 12:03:13 GMT -5

wow. awesome work as usual bill!

|

|

|

|

Post by wbill76 on Aug 21, 2014 12:33:31 GMT -5

Andy, one thing I learned when I did the Z-38 destroyer was that not everything is best handled when off the sprue!  Sometimes you can leave it on the sprue and take advantage of the added strength it gives to do stuff like the drilling-out or clean-up...or even assembly. Kind of like working with the MK tracks, sometimes it's better to leave yourself a 'handle' to make life a bit easier. Rob, the official parts count on the kit box top is 630+...now you know why!  Foenetik Foenetik, thanks for stopping by as well, appreciate the comments!

|

|

|

|

Post by TRM on Aug 21, 2014 16:39:36 GMT -5

...the official parts count on the kit box top is 630+...now you know why!  C'mon now...that is half of most Pz. Kits from DML!  |

|

|

|

Post by Leon on Aug 21, 2014 16:46:07 GMT -5

WOW awesome work on the search lights Bill.  |

|

|

|

Post by wbill76 on Aug 21, 2014 19:00:55 GMT -5

T, that's true...but then those parts counts include 200 for just the tracks!  Pick your poison...  Leon Leon, thanks, those searchlights go all over the decks in different places so couldn't help but jazz them up a bit.

|

|

|

|

Post by dupes on Aug 22, 2014 8:00:46 GMT -5

Nice work! It's stuff like that that kills build progress for me. Good on you for banging it out.  |

|

|

|

Post by wbill76 on Aug 22, 2014 9:22:42 GMT -5

Nice work! It's stuff like that that kills build progress for me. Good on you for banging it out.  Thanks Dupes! Building a ship is a different animal for sure, but progress can be measured in different ways to keep the mojo going. I try to break it up into different types of sub-assemblies/modules while still working towards the whole 'bring it all together' point. Otherwise it can seem like you're drowning (no pun intended) in a sea of little stuff! |

|

|

|

Post by wbill76 on Aug 22, 2014 16:27:44 GMT -5

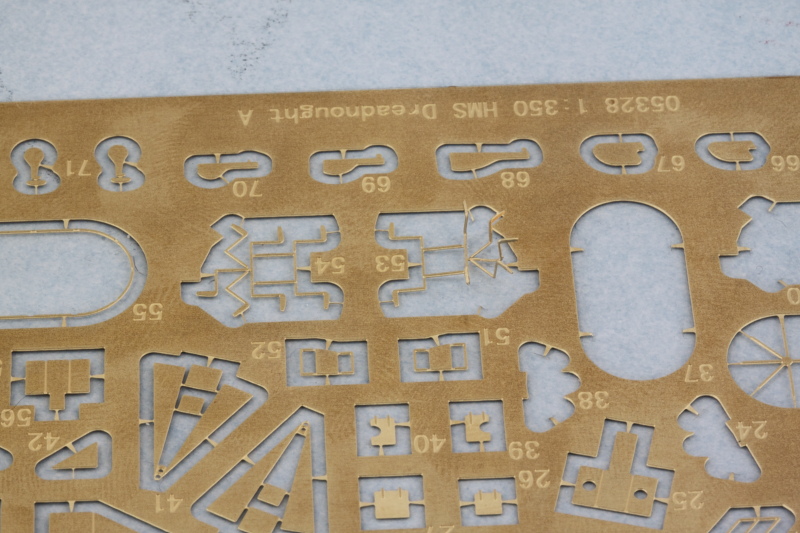

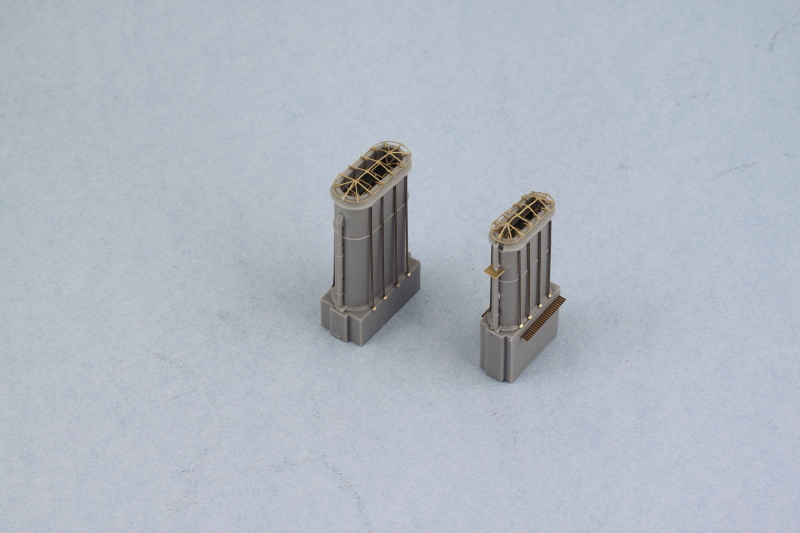

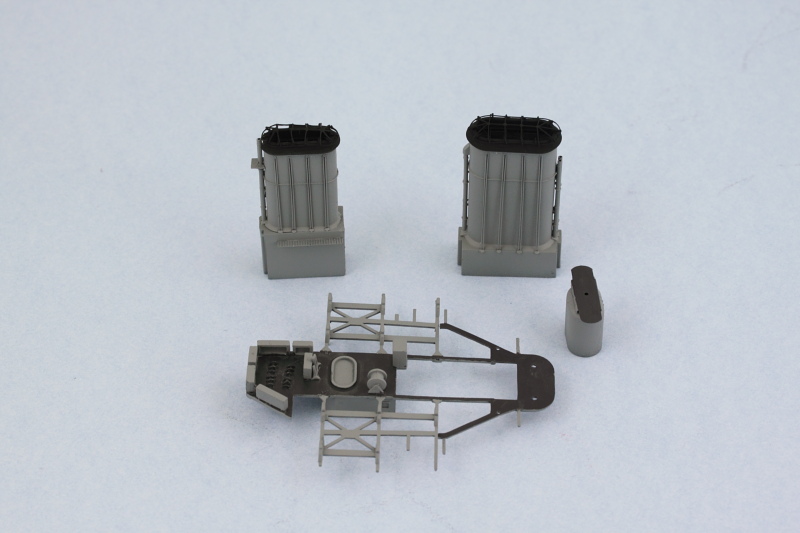

Lots of progress to report today. First up were the baffles and screens for the funnels. Trumpeter provides these as multiple PE parts (5 different parts for each funnel) and they are all extremely fine/fragile. The internal baffles are probably the most fragile as they require a lot of bends but the part itself isn't that sturdy to begin with. One thing that Trumpeter does that I like is they provide their PE with a laminated adhesive sheet...if you only peel off the top sheet, the bottom sheet remains stuck to the back and you can use that to your advantage for parts like this. By only freeing one leg at a time and bending it up into place, it was possible to get all the legs into position where needed...then one last cut to free the baffle from the fret.  Then the real fun begins...I opted to glue the baffles into place first inside the funnel cap using liquid glue, then added the outside ring, and finally the top portion of the screen. The funnel tops are only dry fit for now to make it easier to paint them separately from the funnel stacks as masking due to all the PE is clearly not an option.  After studying the rigging diagrams, I decided to add some rings for the signal flag lines that will be rigged later on. I used the fine copper chain that came with the Hunter deck and clipped out 12 links, cut them in half with fine wire cutters, and glued them in place with CA.  Then it was finally time for some more paint to fly...I primed everything with Flat Black since I needed to spray some anyway for the funnel tops. The turret tops were sprayed with Panzer Gray and everything else got the same custom gray mix that was applied to the hull. In order to paint the 12 pdrs, I stuck them in small blobs of blue tack putty and then stuck the putty to the masking tape so I could paint them more easily since they have mount pins on their bases.  That will get a chance to cure up and this weekend will see more detail work in terms of getting the gear installed on the first super deck level so I can secure the boat deck and continue to work my way up in the superstructure. |

|

|

|

Post by Leon on Aug 22, 2014 17:09:39 GMT -5

Fine looking PE and paint work Bill.Your making good progress.  |

|

|

|

Post by TRM on Aug 22, 2014 19:06:21 GMT -5

Some really great PE work there Bill!! Smart thinking my friend! Love seeing the color going down on all theres pieces!! Soon the jigsaw puzzle will all come together!!  |

|

|

|

Post by wbill76 on Aug 22, 2014 19:21:37 GMT -5

Thanks Leon! That baffle arrangement is one that would try the patience of a saint if you tried to assemble it the way Trumpeter wants you to in the instructions.  T T, I swear that some of these kit designers don't actually TRY to build the kits they put out...they just use CAD for everything and voila! Getting this round of painting done should set me up for a nice little bit and lots of tweezer-installs to get the stuff in place now.  |

|

|

|

Post by deafpanzer on Aug 23, 2014 9:26:44 GMT -5

STUNNING!!! Still you are not helping me... LOL Can't wait to see more!

|

|

|

|

Post by wbill76 on Aug 23, 2014 16:30:57 GMT -5

Thanks Andy! Better look away now then...  |

|

|

|

Post by wbill76 on Aug 23, 2014 16:42:03 GMT -5

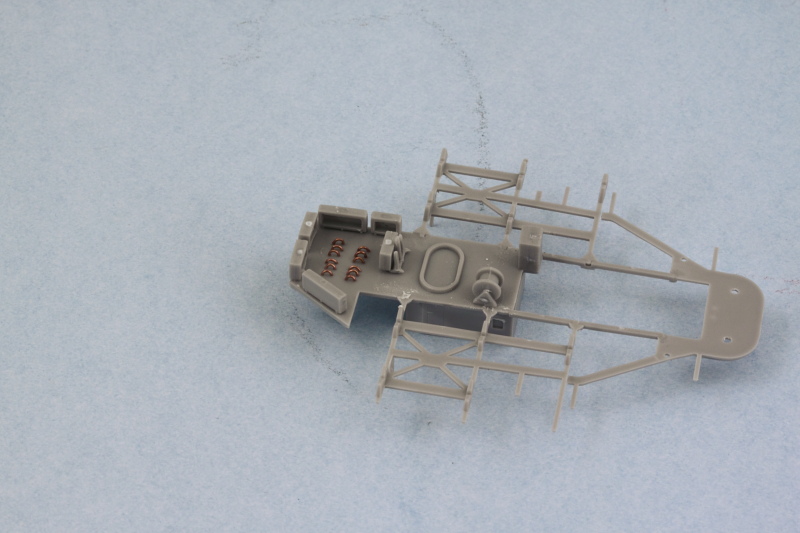

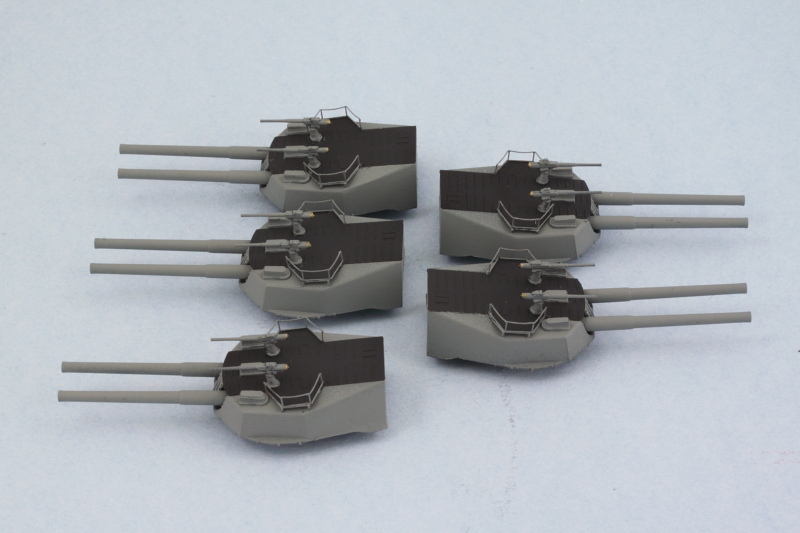

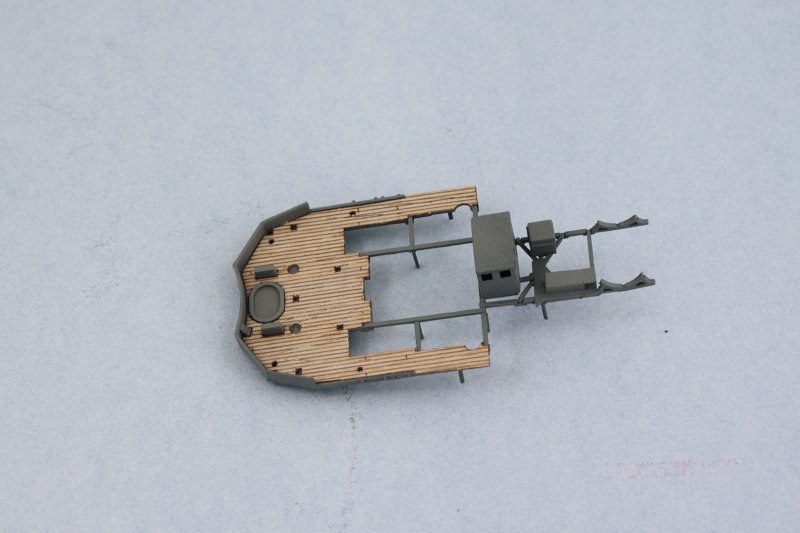

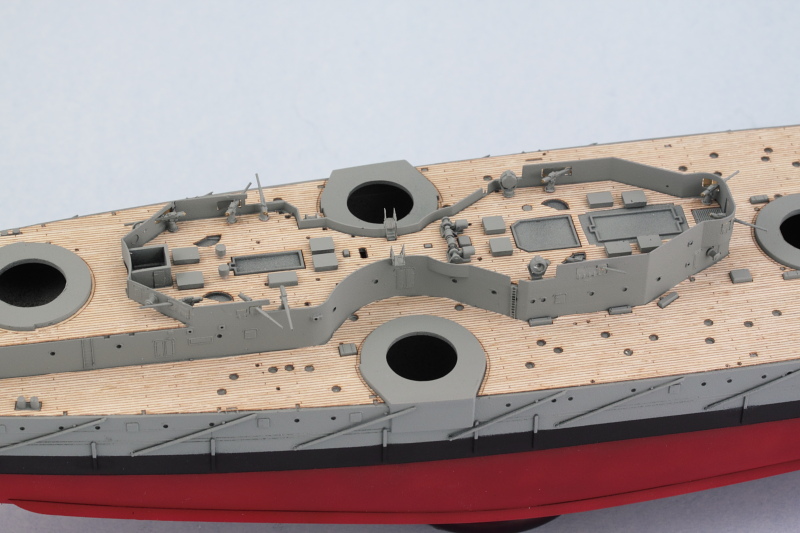

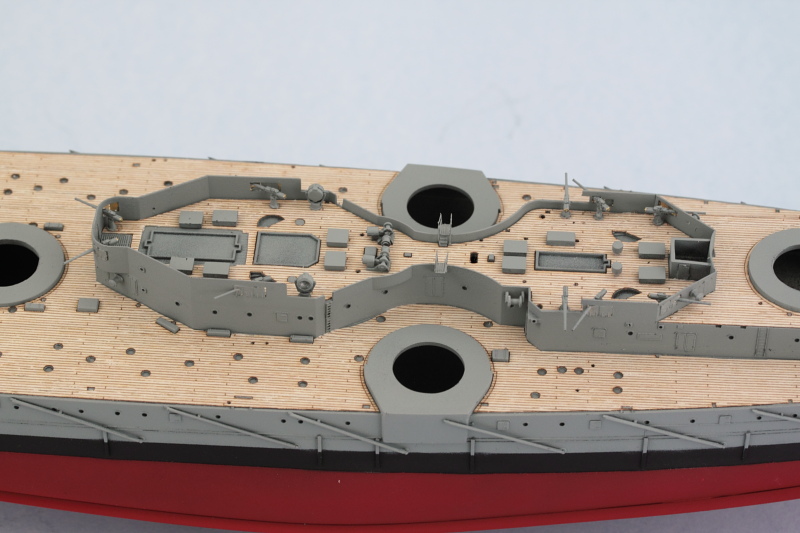

Building on the paint progress from yesterday, today's efforts were all in the detail department. Turrets received their 12 pdrs along with the Eduard platforms and guard rails. The 12 pdr mounts as-is were all pointing downward, so some gentle pressure on the breech portion of the gun 'elevated' them so they would sit at a level height once installed into the platforms. Took a little trial-and-error but eventually I got all 10 sitting at pretty close to the same height. The 12 pdrs got a little extra detailing in the form of some Model Master Non-Buffing Metalizer Brass applied to their breeches.  The funnels got their caps permanently installed and the signal flag deck area and aft searchlight platform were painted with Panzer Gray to detail the crew walk areas. Same thing for the aft conning tower's fire direction platform. I'll wait to install some railings for it until I'm ready to finally install it in place to avoid any possible damage or complications.  Front portion of the boat deck received its wood decking as well as a permanent install. This is much easier to handle with the deck 'loose' vs. fixed and today was as good a time as any to check that off the list.  The boat deck levels are still dry fit only at this point as I need to work on the super deck level details next. Doesn't hurt to do a quick check though to make sure everything's still playing nice with each other.   |

|

|

|

Post by Leon on Aug 23, 2014 18:42:28 GMT -5

WOW!!!! Bill you really made great progress today  .I am really liking the looks of the wood decks.Good to hear everything is playing nice.  |

|

|

|

Post by wbill76 on Aug 23, 2014 19:34:12 GMT -5

Thanks Leon! Today was a productive day...tomorrow should see even more little stuff installed on that super deck interior before the boat deck gets added. Interestingly enough I've been reading about the general history/circumstances surrounding HMS Dreadnought and the whole diplomacy/naval arms race that led up to WWI. One of the side notes they pointed out that was revolutionary in Dreadnought's design was that it didn't use any watertight doors between sections of the ship...instead there were no doors, every compartment was horizontally isolated from the others and access was only possible through vertical ladders and such. If a compartment was opened to the sea, the crew in that compartment were largely doomed, but the ship would continue to fight.

|

|

|

|

Post by Leon on Aug 23, 2014 19:41:27 GMT -5

Nice bit of history Bill.Ships have come along way since then.  |

|

modelfreak72

Full Member

Member since: January 2012

Why worry, each of us is wearing an unlicensed nuclear accelerator on his back.

Posts: 1,479

Jan 28, 2012 23:21:46 GMT -5

Jan 28, 2012 23:21:46 GMT -5

|

Post by modelfreak72 on Aug 24, 2014 11:21:25 GMT -5

Hot dam Bill! She's coming together real awful purdy!  |

|

|

|

Post by wbill76 on Aug 24, 2014 19:42:58 GMT -5

Hot dam Bill! She's coming together real awful purdy!  Moving ahead slowly one step at a time! Glad you're enjoying the voyage with me.  |

|

|

|

Post by wbill76 on Aug 24, 2014 19:43:12 GMT -5

I started in on the super deck's interior details today and immediately encountered an issue when it came to installing the 12 pdrs. The added fractional millimeter of the wood deck is a partial contributing factor but the bulk of the issue had to do with the bases of the guns and how they needed to mount into the various slots in the super deck structure. The mount pins work great for open spaces like the turret tops or the open decks...but when they have to fit into the tight spaces like most of the superdeck's openings, it was virtually impossible to get them into position. I ended up removing all of the mount pins and sanding the bottoms of the bases smooth and using CA gel to mount the guns into position over the mount holes instead. It's also worth noting that while the guns themselves are installed in Step 16, the exterior port covers that also need to line up with the gun barrels aren't dealt with until Step 26 and they have to fit just so together to look right. So much flipping back and forth in the instructions was called for as I worked on getting the guns installed as a result and it's a slow and tedious process as the panels have only a very tiny contact surface for gluing. I suppose you could also opt to pose the covers in the down position and have less hassle that way but it definitely doesn't look the same. I also hunted through the instructions and added all the little exterior parts like the hose reels, ladders, and the walkways for the wing turrets. I also discovered that the rectangular hatch covers D29 are meant to sit right up against the aft funnel's base, so they have to sit just right for there not to be any interference. I glued those in place first and then left the funnel sitting in position until the glue had set to make sure there wouldn't be any issues later on in that area.   Next up will be getting the boat deck components in place and continuing the upward climb on the superstructure components. I should also note that the Wood Hunter provided coal scuttle PE inserts are a perfect fit for the openings in the deck vs. the Trumpeter items which are too small, I tried out a couple that were needed for the super deck and they fit like a glove. |

|

|

|

Post by TRM on Aug 24, 2014 22:31:22 GMT -5

That's the stuff right there brotha!! Nice clean work (like I would expect otherwise)!!  She is starting to get that nice busy look to her!! |

|