|

|

Post by tonylee-Rest In Peace on Aug 24, 2014 22:42:35 GMT -5

M E R C Y Tex   Tony lee |

|

|

|

Post by wbill76 on Aug 25, 2014 11:59:30 GMT -5

Thanks Todd, the irony of course is that about 80% of that all gets hidden away once the boat deck is fitted and all the boats added...but it's there for the curious who go poking around!  Tony Tony, just think of it of a giant sea-going SPG platform.  |

|

|

|

Post by deafpanzer on Aug 25, 2014 12:18:38 GMT -5

WOW! I have to say the deck looks AMAZING!!! Lots of work but worth it...

|

|

|

|

Post by wbill76 on Aug 25, 2014 13:08:19 GMT -5

Thanks Andy! Slowly but surely it all gets added and installed.  |

|

|

|

Post by Leon on Aug 25, 2014 17:03:18 GMT -5

Glad to hear you got the turret issues solved Bill.Starting to look like a ship now.   |

|

|

|

Post by wbill76 on Aug 25, 2014 20:13:01 GMT -5

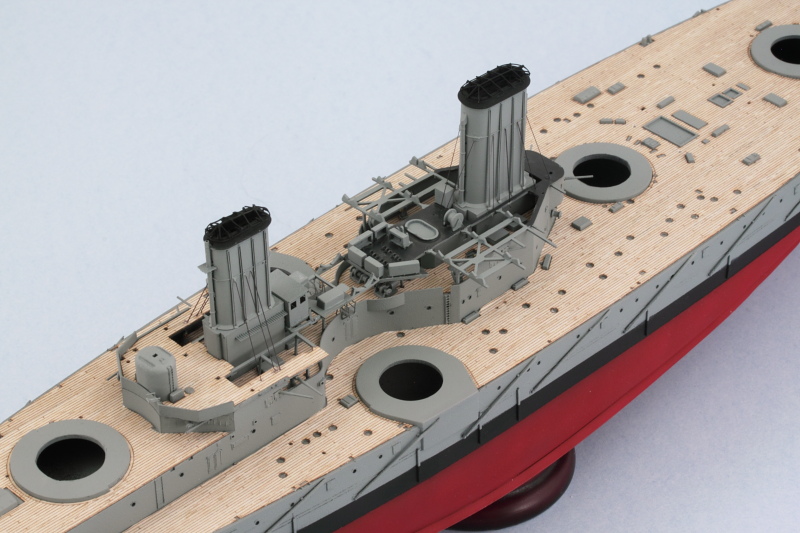

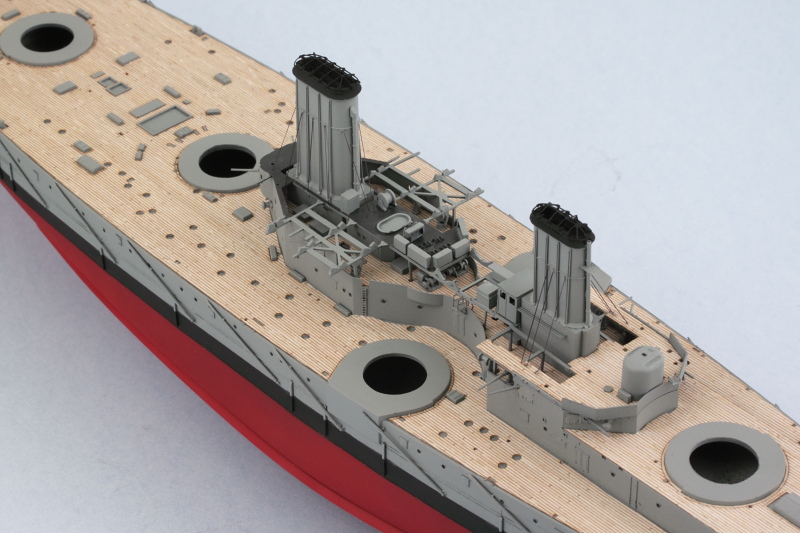

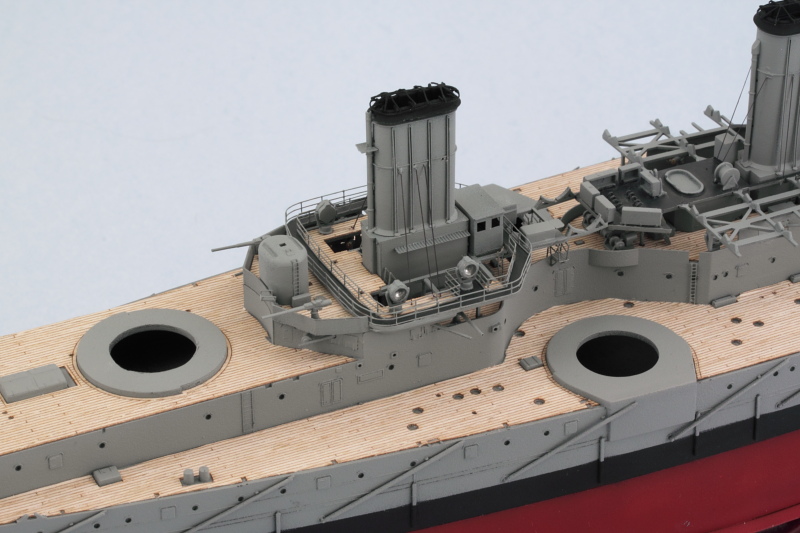

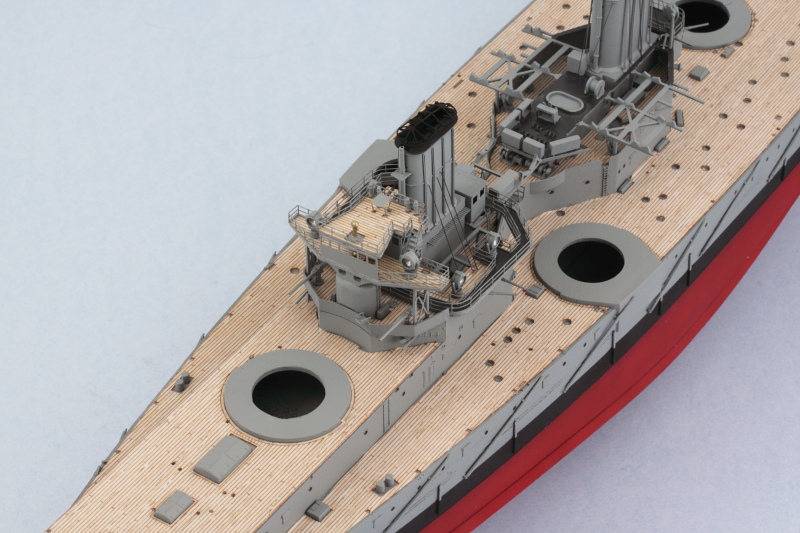

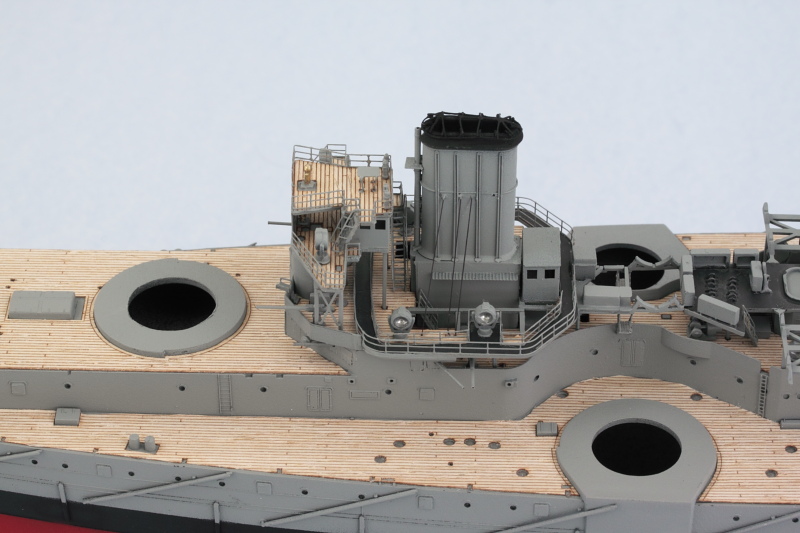

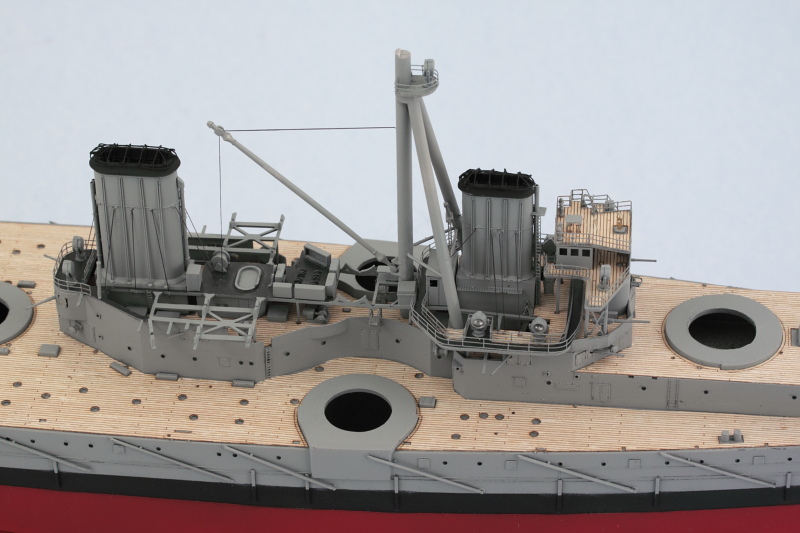

Thanks Leon! Today made even more progress in the 'looking-like-a-ship' department.  Building on yesterday's efforts, I permanently installed the boat deck levels in place over the super deck. Funnels were also permanently installed after I used a #80 finger drill to create mount points for the bracing wires. Wires were added using the Fine grade of black EZ Line and CA. The final pair of bracing wires for the fore funnel will be added once the mast tripod is in place since they connect to the legs vs. down to the deck itself.   There's still more detail work for the boat deck level including the aft searchlights and railings, the pair of 12 pdrs on either side of the conning tower, and the admiral's walk left to do before I can move on up to the bridge deck. |

|

|

|

Post by Leon on Aug 25, 2014 20:26:52 GMT -5

Looking really good Bill,Those bracing wires look like some delicate work to install.  |

|

Foenetik

Full Member

November '24 Showcased Model Awarded

November '24 Showcased Model Awarded

Member since: March 2014

Posts: 609

|

Post by Foenetik on Aug 26, 2014 9:08:49 GMT -5

decking looks top notch.

|

|

|

|

Post by wbill76 on Aug 26, 2014 9:24:58 GMT -5

Thanks Leon! The bracing wires are made using EZ-Line which helps greatly in terms of making sure they are tight vs. monofilament or ordinary thread/string. First time using the stuff and took a little bit of trial and error at first to get the hang of it but then went faster. Pretty neat stuff IMHO! I can definitely see why the airplane guys love it for antenna wires or biplane bracing. Tony, thanks as well, got love the look of real wood for sure!  |

|

|

|

Post by mrt51 on Aug 26, 2014 9:29:41 GMT -5

Taking notes! I like this a lot.

Terry

|

|

|

|

Post by wbill76 on Aug 26, 2014 11:51:50 GMT -5

Thanks Terry! Much appreciated  |

|

|

|

Post by wbill76 on Aug 27, 2014 17:04:22 GMT -5

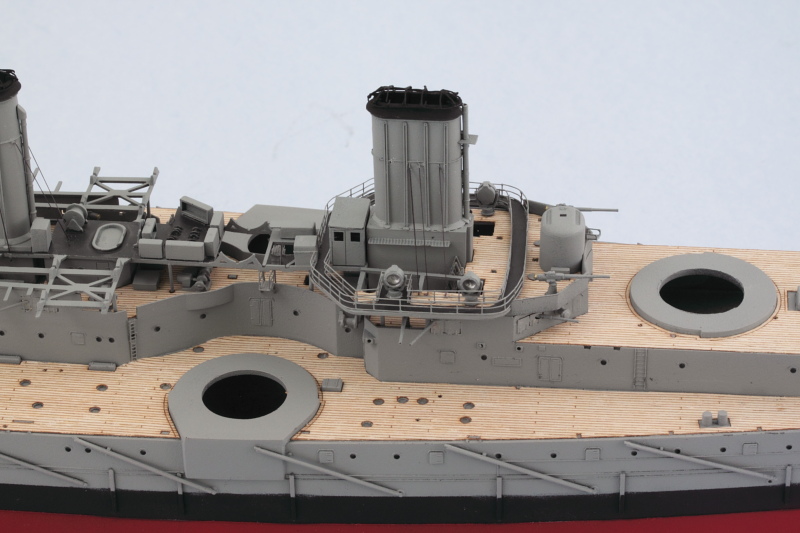

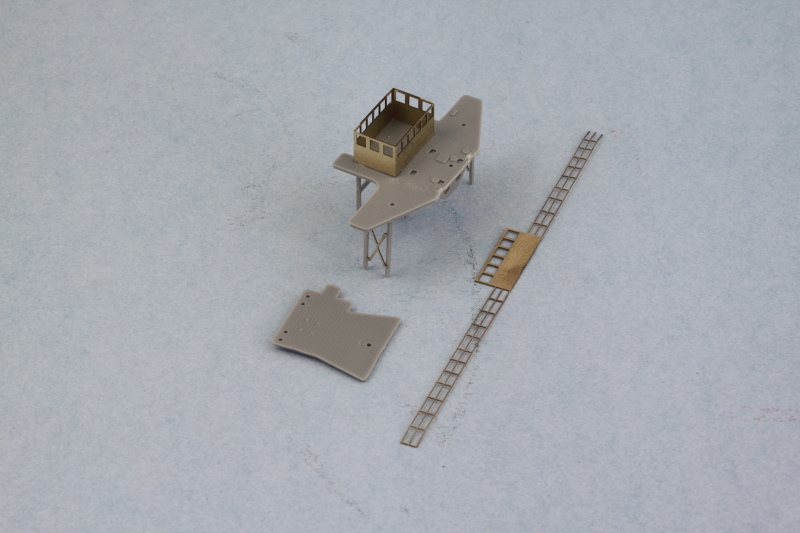

Made some more progress on the boat deck level. The next element that needed attention was the admiral's walk. I immediately encountered an issue with its fit in relation to the admiral's day cabin and the little box on the other side of it. I'm not sure if this was a combination of using the Eduard replacement for the cabin, a fit issue with the kit part, or some combination/variation of the two. Regardless, I needed to modify the walk by cutting a notch into it so it could clear the box, part B6, which the instructions have you install in Step 22 prior to the walk going in. I also added the side sponsons (B8/B11) to the walk instead of installing them directly to the superstructure sides as I wanted to sure they would fit flush with the walk and not cause issues. Last but not least, I also added the supports, F23, that the instructions would have you install independently in Step 26. That's not a good idea as they have to attach at an angle and getting that right is pretty difficult without using the walk itself to ensure they sit correctly.  While the walk supports were setting up, I added the PE access ladders from the super deck up to the boat deck and worked on the aft searchlight platform as well. I found an error in the Eduard railing PE instructions, the correct railing for this area is #12, not #4. #4 gets used on the small searchlight platform on the main mast and is too small to go in this area, so a small note for anyone looking to use that set! I used the small section of railing that I clipped off from the fire direction control platform earlier as the back railing section for this platform, installed the front railing, then added the pair of searchlights to complete the aft portion.  Then the real fun began in terms of the railings for the admiral's walk because of all the complex curves involved with it. I opted for the Eduard rails instead of the Trumpeter railings as the Eduard railings have the correct lower height vs. the Trumpeter railings which are all the same standard height type and the Eduard rails have the added bonus, at least for the inner rail, of having etched bend lines to aid with the shaping of some of the key areas around the searchlights. I added the inner railing first, then added the 4 search lights, then the outer rail came last. The forward pair of 12 pdrs rounded things out as well.   Next up will be working on the bridge components so I can get them integrated in fully in with the rest of the superstructure. |

|

|

|

Post by Leon on Aug 27, 2014 17:13:04 GMT -5

The detail work is adding up Bill and looking really great.  |

|

|

|

Post by wbill76 on Aug 27, 2014 17:49:34 GMT -5

Thanks Leon! Still a lot to go on this one but making progress one level at a time.  |

|

|

|

Post by TRM on Aug 27, 2014 20:19:08 GMT -5

Some fine looking railing work Bill!! Loving this build for sure!! Just noticing the searchlight (like a dope)...excellent!!!

|

|

|

|

Post by deafpanzer on Aug 28, 2014 10:13:20 GMT -5

Now you are scaring me... I am not sure if I am ready! LOL Thanks for answering my question on FB regarding having rails painted before gluing them to the ship.

|

|

|

|

Post by wbill76 on Aug 28, 2014 13:36:56 GMT -5

Thanks Todd! Got to keep a sharp eye out.  Andy Andy, don't be scared. It's like eating an elephant. Just one bite at a time.  |

|

|

|

Post by wbill76 on Aug 30, 2014 10:22:16 GMT -5

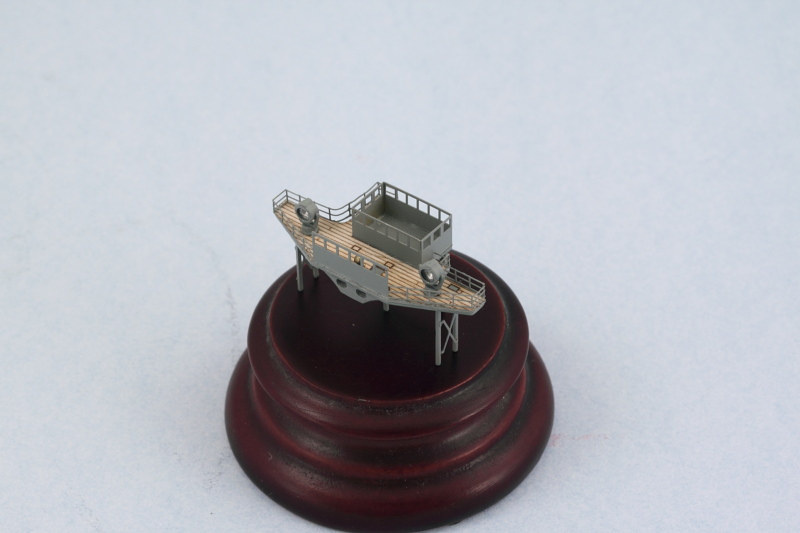

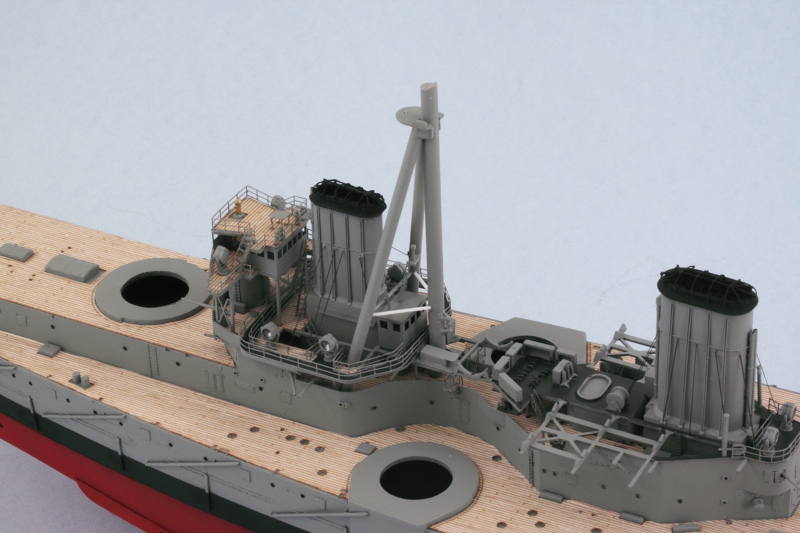

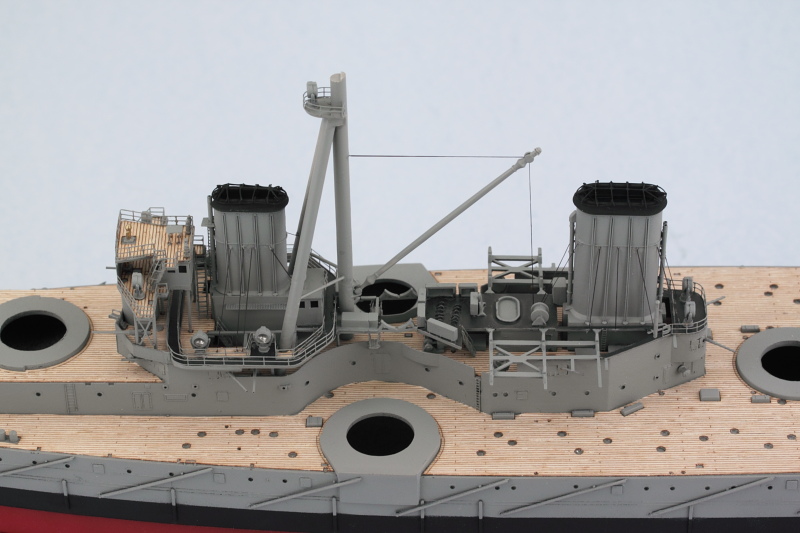

Assembling the two-level components of the bridge deck is a delicate operation that requires a lot of patience, mostly due to the fact of the way its supported relative to the boat deck. I decided the best way to tackle it was to install all the support legs first on the underside of the platform and use the conning tower and the openings in the wood deck to ensure everything aligned properly and then let it sit overnight so the glue could set thoroughly before moving ahead. Before doing that, I also made some minor adjustments so I could use the Eduard bridge house components instead of the kit-supplied parts. The notches in the platform were filled with putty and a combination of the little tabs cut free from the kit part where needed and then the brass house installed with CA gel. After all the legs had set up, I cut the cross braces from the Eduard support legs (which are too 'spindly' IMHO to be used by themselves) and attached those to the styrene legs to add a little more detail.  Out came the airbrush for some quick paint work and then the real work of assembling the two levels together began. The first level received its wood decking and then the Eduard external bridge face and railing were installed. The searchlights and compass stand were added to complete the first level.  Moving up to the 2nd level, it too received its decking and was glued in position over the bridge house. Compass stand and other details were installed prior to the railing to make life a little easier there. The chart table is extremely delicate as Trumpeter provides it as a PE part and the legs aren't very sturdy, so great care is needed there. The railing for this area has to take on a lot of complex bends/shapes, most of which the Eduard rail has pre-etched to help with, but it's still a delicate dance. I bent it into shape first, brush painted it by hand, then installed it in place. Last little piece of the puzzle was the Eduard-supplied access ladder to the upper deck.  Time for the moment of truth, the whole module was installed in place, integrating with the conning tower and boat deck below.  Rounding things out, the Eduard tall access ladder was added to the rear of the bridge structure.  Next up will start work on the masts. |

|

|

|

Post by Leon on Aug 30, 2014 10:38:45 GMT -5

WOW!!!!  awesome work on the two levels Bill.Just keeps getting better and better.   |

|

|

|

Post by wbill76 on Aug 30, 2014 11:14:57 GMT -5

Thanks Leon! Was a real challenge figuring out how best to handle it all as there isn't a convenient place to hold it once you start stacking the decks and railings.  Thank goodness for locking tweezers!  |

|

|

|

Post by deafpanzer on Aug 31, 2014 13:52:44 GMT -5

AMAZING!!!!! I am about to place an order for wooden deck as I am still doing research on my ship. Bet it was fun adding the deck inside the bridge...

|

|

|

|

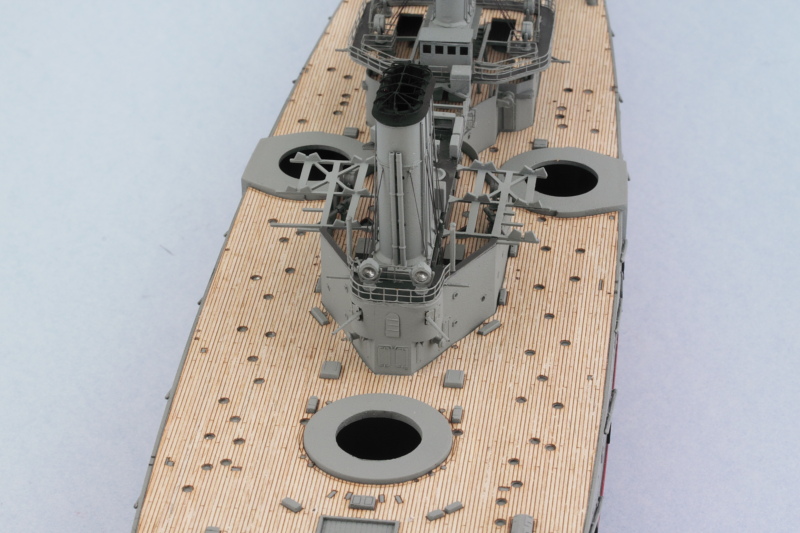

Post by wbill76 on Aug 31, 2014 16:24:24 GMT -5

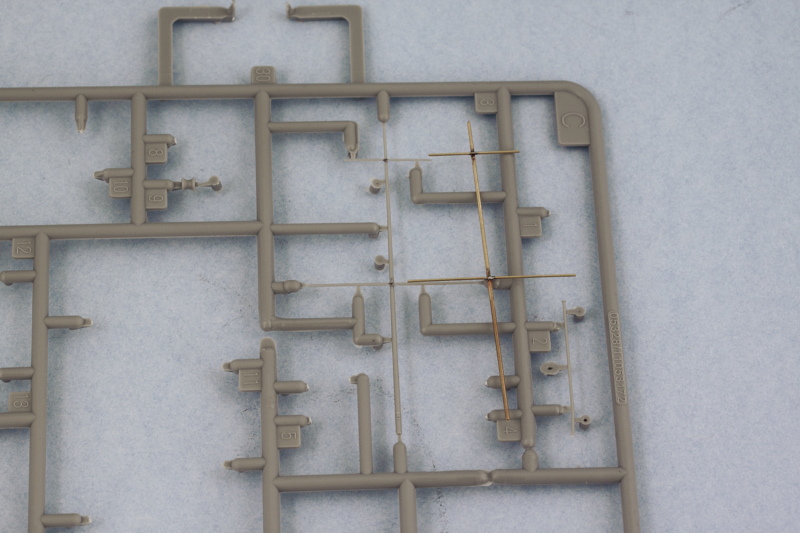

Thanks Andy! Glad to hear your Indy project is still steaming along.  As for the deck inside the bridge, the neat thing about it all is that it just drops in place...then you add the necessary parts on top of it. Not too difficult but you do have to think ahead a bit with it.  I started in on the masts with the foundation of the tripod elements needing attention first. I left off the coaling derrick arm to allow more flexibility in its positioning for later and also to keep it out of the way of trying to install its host leg into position. Trumpeter designed it with a notch near the base that interacts with the boat deck level to install it in the correct position and having the derrick in place would make that much more frustrating than it should be. I airbrushed all three legs after adding in the little platforms to the two front legs and the searchlight platform to the rear leg. All three legs were installed into the super deck and then aligned where they all meet at the top. I left off the little PE support piece, PE33A, for the searchlight platform's underside until after things had set on the three legs to avoid the possibility of it getting knocked loose and lost to the carpet monster. One detail that I noticed in the Kagero 3D book that was missing were the three triangular braces between the legs, so I used some 0.6mm styrene rod to recreate those. The front brace went in first, followed by the PE ladders for the little elevated platforms, then the rear braces were added. I also added the last two funnel stay lines that connected to the tripod legs to round things out there.  Once all that had set up, I hand painted the braces and added the searchlight and railing to the platform. The derrick came next and I had to decide whether to position it as Trumpeter wanted it or how the Kagero book shows it in the 'stowed' position. The Kagero position would complicate a lot of things including the aft conning tower, the way the signal flag lines would be rigged, and also possibly interfere with the boats...so I decided simpler is best and put it in the Trumpeter designed angle. May not be 100% accurate but it's something I can live with.  I also added in the access ladder, PE48A, for the front funnel that reaches from the super deck to the weather station platform. Had I known how tight that space would get at this stage, I would've installed it sooner but I had overlooked it in the instructions under Step 30.  Next up will be the complex task of working on the crow's nest platform with all of its PE parts and the upper portions of the front masts and cross arms. Since those are going to be replaced with brass rod to take the strain of rigging, I've got to devote some careful study to that and decide how best to tackle. |

|

|

|

Post by Leon on Aug 31, 2014 18:37:15 GMT -5

Nice progress on the mast and derrick Bill.  |

|

|

|

Post by wbill76 on Aug 31, 2014 19:13:14 GMT -5

Thanks Leon! one step forward at a time.  |

|

|

|

Post by deafpanzer on Sept 1, 2014 10:33:48 GMT -5

Wondered if you did that... sure takes a lot of planning to build it effectively. Looking good my friend!

|

|

|

|

Post by wbill76 on Sept 1, 2014 17:10:19 GMT -5

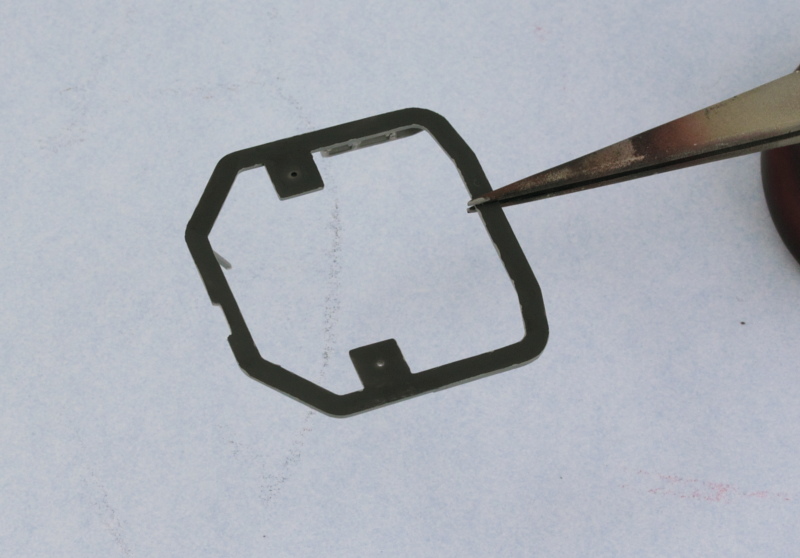

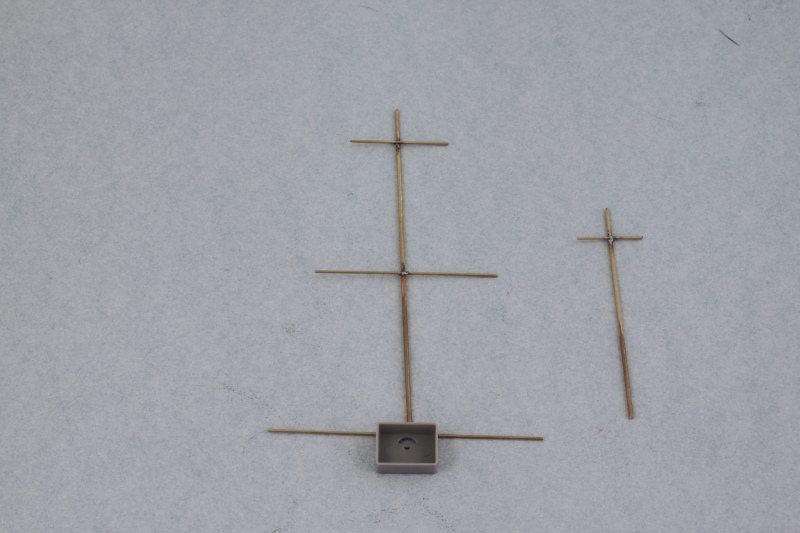

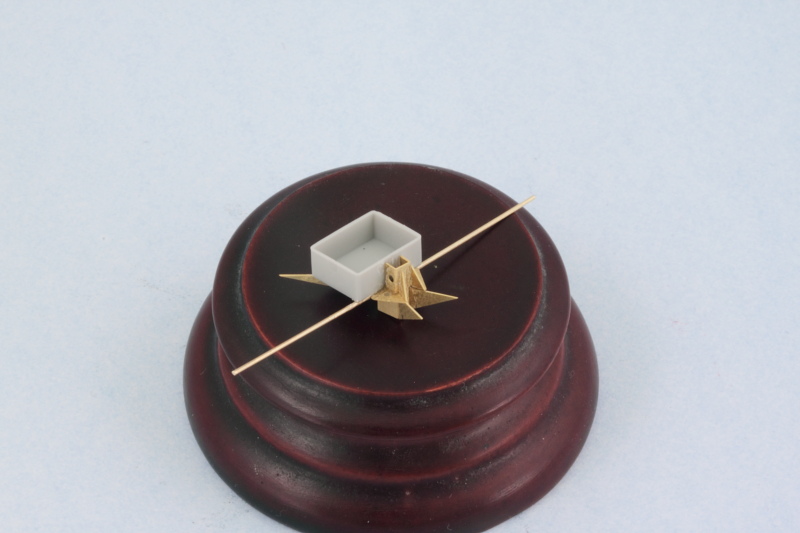

Thanks Andy! Ships have their own secrets that you have to work at but still a fun process!  Speaking of that... Hope everyone had a great Labor Day holiday! Efforts today certainly lived up to the 'labor' part at least but I had fun working on the main mast and its components. I decided to replace the kit-supplied styrene mast-crossarm piece, C3, with brass rod to provide added strength and durability for this critical piece of the superstructure. My LHS stocks several different diameters of brass rod in their R/C aircraft section and I picked out different lengths of varying diameters and brought them home to see which would do the trick since the cross arms are thinner than the mast itself. I used a Dremel cordless tool and a cone-shaped grinder tool to introduce a taper for the mast but left the cross arms as-is given their relative thinness to begin with. Once I had the main mast done, I cut out the three cross arms again using the kit part as a guide for their length, and then marked their center points with a sharpie. Using a triangular needle file, I notched the main mast in the appropriate places so the cross arms would have a solid contact point. Once all that prep work was done, it was time to solder the cross arms to the mast. I have a Weller variable temp soldering iron and while it was warming up, I used a piece of fiber board and some T-pins to position the mast and cross arms correctly. I used silver-bearing solder paste to place small beads over the join, the soldering iron provided the heat, and voilà! Brass mast and cross arms.   While I was at it, I also created the rear mast and cross arm combo for the aft mast. The third cross arm for the main mast integrates directly with the fire direction platform, so it was secured in place with CA gel separately from the main mast. This also makes life easier when attaching all the PE bits for the underside as the cross arm becomes a convenient 'handle'.  Speaking of PE, the next steps require lots of patience and test fitting with the tripod to make sure the alignment is correct on all the underside supports for the fire direction platform. There are 5 separate parts and the locater marks that Trumpeter provides are a helpful guide but some adjustments are still needed to get the parts to line up correctly and play nice.  If using the styrene masts, Trumpeter has you secure the mast to the platform before adding the rear bracket and rigging extensions. I did the reverse for handling reasons due to the added weight of the brass masts and also to create an added support structure for the mast itself. The rear bracket is made up of 5 different PE parts that all have to come together just so to create the right effect and the Trumpeter instructions aren't super clear on how they all come together. Fortunately the Kagero 3D book includes a very nice look at this area and helped greatly in terms of getting it all lined up properly.  With that done, it was time to pair up the mast and cross arms with the platform. I flattened the rod with a square file so it could have a greater contact surface with the back of the platform and used CA gel to give me a little work time to ensure it was positioned at the right height and alignment with the third cross arm. Once the CA gel had grabbed hold, I used some Aves epoxy putty to stuff the base of the rear clamp structure so it would provide some greater stability and hold for the mast over the long term. A dry-fit test shows everything is lining up properly even though the angle on the camera isn't quite perpendicular.  Not a bad day's work, the second mast should go faster now that I've learned the 'tricks' of the PE from doing the first one. |

|

|

|

Post by Leon on Sept 1, 2014 18:48:55 GMT -5

Fantastic work on the mast and platform Bill.  |

|

|

|

Post by wbill76 on Sept 1, 2014 19:30:22 GMT -5

Thanks Leon! Definitely made the day go by in a flash...I thought I'd get both masts/platforms done but as usual, eyes were bigger than stomach!  |

|

DeafStuG

Full Member

Member since: May 2013

..

Posts: 1,283

|

Post by DeafStuG on Sept 1, 2014 19:32:47 GMT -5

Very neaty and great works with your shipyard-bench.

|

|

|

|

Post by wbill76 on Sept 1, 2014 20:04:47 GMT -5

Thanks Jeremy! I'm really enjoying this one and the shipyard-bench is staying busy, always a good thing.  |

|